Universal welding of metals by MIG and MAG methods.

MIG and MAG welding are some of the most widely used metal joining processes in industry, construction and machinery manufacturing. At Metallbauform, we offer professional arc welding services with consumable electrodes in protective gas shielding - both inert gas (MIG) and active gas (MAG). Due to the high efficiency and speed of the welding process, these methods are ideal for mass production, joining steel structures and during assembly work.

We realize welding of black steel, stainless steel, aluminum alloys and other metals. Our experience allows us to adjust the parameters of the process to the specifics of the material and the thickness of the welded elements. Each weld is performed with attention to the quality, aesthetics and strength of the joint.

We realize welding of black steel, stainless steel, aluminum alloys and other metals. Our experience allows us to adjust the parameters of the process to the specifics of the material and the thickness of the welded elements. Each weld is performed with attention to the quality, aesthetics and strength of the joint.

MAG and MIG welding delivers fast, strong joints for construction and industrial assembly.

We use MAG and MIG welding for efficiency in manufacturing and frame production.

Modern stations and certified welders

We have fully equipped MIG/MAG welding stations and a qualified staff of certified welders in accordance with PN-EN ISO standards. We work with high quality welding equipment, which allows us to obtain welds of high strength and aesthetics. Our processes are repeatable and controlled - we provide visual testing (VT), as well as penetrant testing (PT) and weld quality documentation upon request.

MIG/MAG welding allows for fast and efficient joining of even thicker sheets and profiles. By using the right wires and gases, we are able to adapt the technology to specific production conditions and customer requirements.

MIG/MAG welding allows for fast and efficient joining of even thicker sheets and profiles. By using the right wires and gases, we are able to adapt the technology to specific production conditions and customer requirements.

Versatility of application and flexible approach

We provide MIG and MAG welding services both on our shop floor and at the project site - depending on the nature of the order. We serve the construction, industrial, energy and structural industries. We weld structural components, frames, tanks, supports, machine parts and much more. For individual customers, we also carry out smaller projects such as railings, fences and utility elements.

We ensure timely delivery, individual approach to each project and technical support at the stage of documentation preparation.

We ensure timely delivery, individual approach to each project and technical support at the stage of documentation preparation.

MAG and MIG welding provides cost-effective strength in thick metal fabrication.

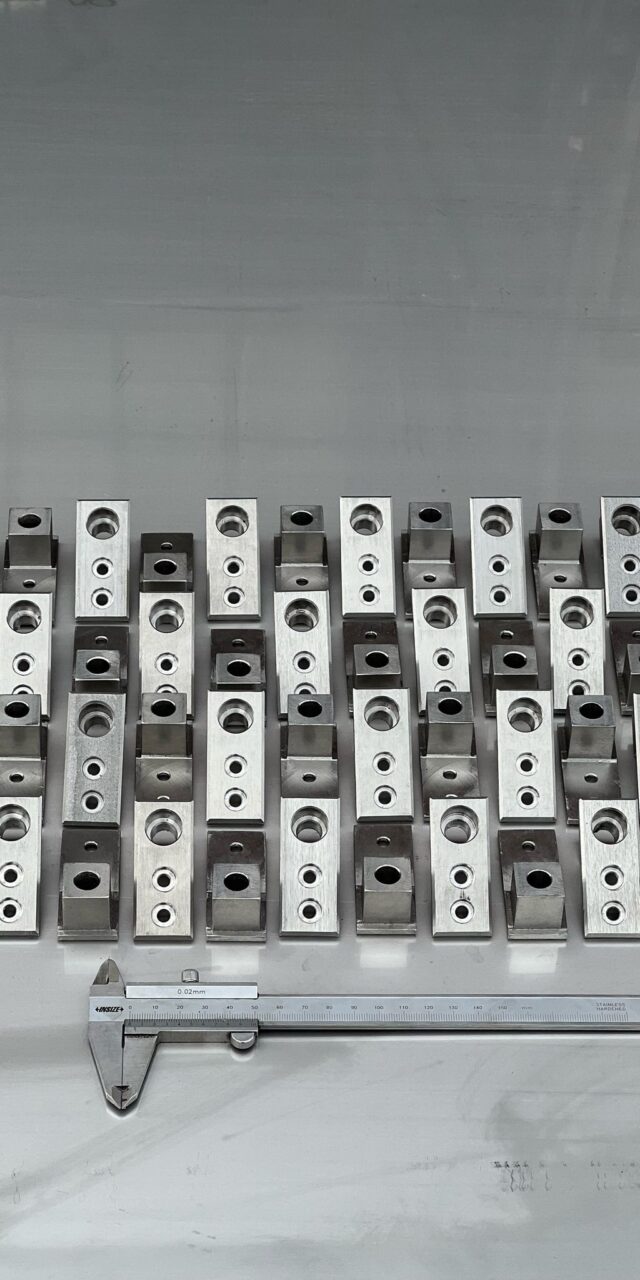

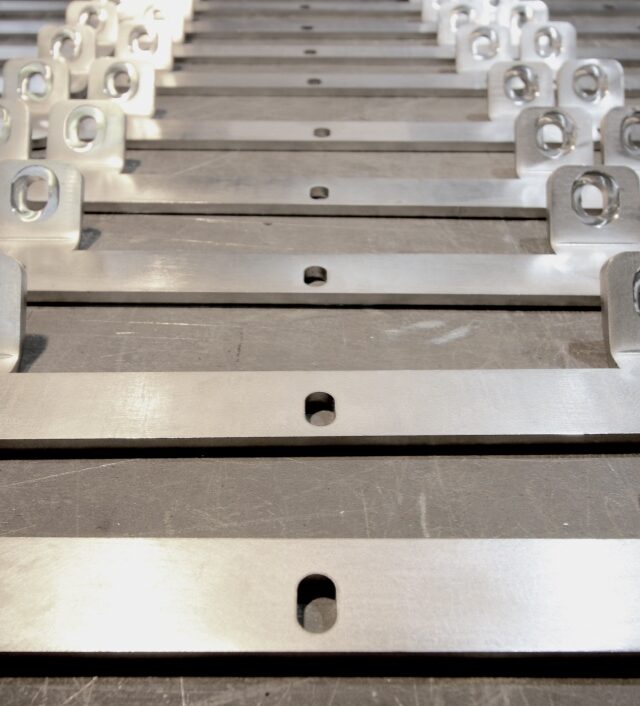

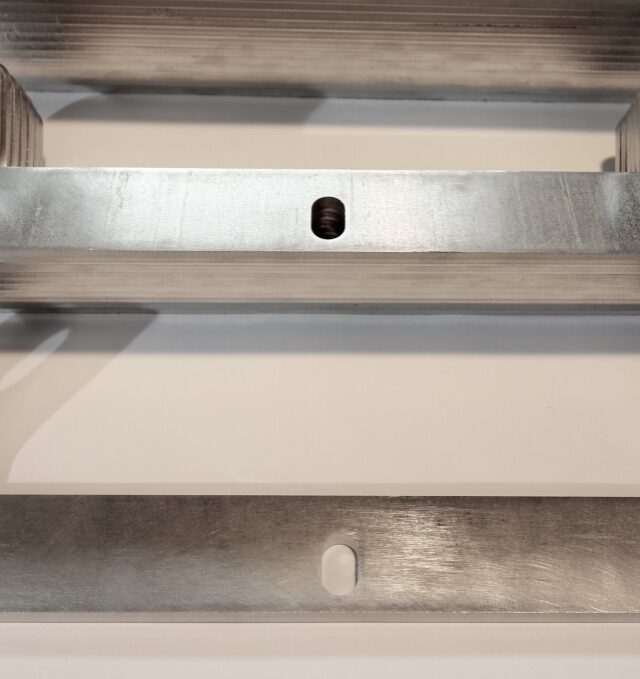

Realizations

ContactContact us

MIG/MAG weldingFAQ

1. What is the difference between MIG and MAG welding?

MIG uses an inert gas (such as argon), ideal for aluminum and stainless steel. MAG – active gas (e.g. CO₂) – is mainly used for black steel.

2. What materials can be welded by MIG/MAG?

Structural steel, stainless steel, aluminum, copper and other weldable metals using electrode wire.

3. Do you offer welding with quality documentation?

Yes, we offer VT, PT documentation and welding certificates according to ISO 3834 and EN 1090.