What is rolling and when is it worth using?

Rolling is a process of plastic processing of metal, which allows to give the material the desired shape without removing its layers. With this technology, it is possible to create cylindrical, conical, arched or non-standard geometry parts. At Metallbauform, we offer professional rolling of sheet metal, tubes and steel and aluminum profiles - both for industrial constructions and for specialized projects. We serve customers in the construction, installation, machinery, energy and many other industries.

The rolling process preserves the continuity of the material's structure, which translates into greater strength and durability. This method is particularly advantageous in the production of load-bearing components, tank casings, pipes, shells, lamp posts or ventilation ducts. It also works well where high forming accuracy is required while maintaining a smooth surface.

The rolling process preserves the continuity of the material's structure, which translates into greater strength and durability. This method is particularly advantageous in the production of load-bearing components, tank casings, pipes, shells, lamp posts or ventilation ducts. It also works well where high forming accuracy is required while maintaining a smooth surface.

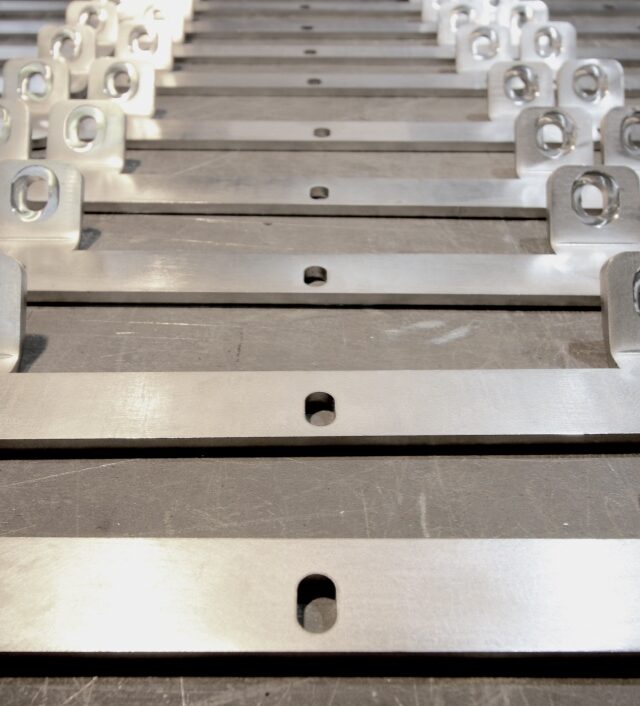

Sheet rolling creates uniform curves for structural and decorative applications.

We roll sheets of various thicknesses with precision-controlled radii.

Rolling machinery park - precision and repeatability

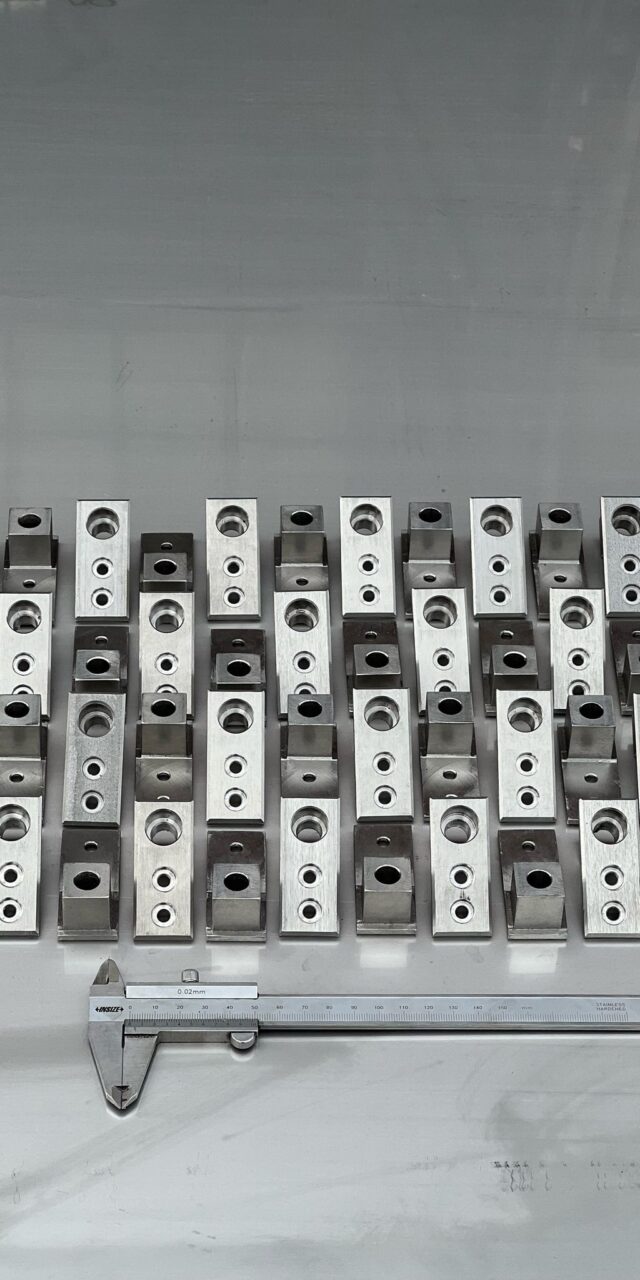

We have state-of-the-art rolling mills for sheet metal, pipes and profiles, which allow us to precisely bend materials of different thicknesses, widths and cross sections. We roll both thin-walled sheets and thick steel plates, as well as tubes and closed profiles. Thanks to the automatic control of the machines, we can achieve repeatable shapes, which is particularly important in mass production and projects requiring high-quality assembly.

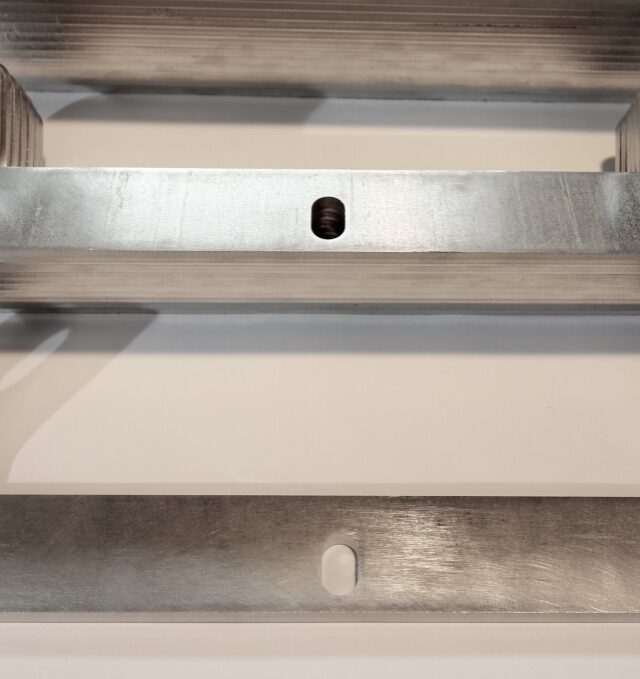

Each stage of the process is monitored - both to ensure that the proper bending radii are maintained and to minimize material distortion. Finished parts are dimensionally checked and adjusted for further processing, such as welding or assembly. If necessary, we also offer a cutting or punching service after the rolling process.

Each stage of the process is monitored - both to ensure that the proper bending radii are maintained and to minimize material distortion. Finished parts are dimensionally checked and adjusted for further processing, such as welding or assembly. If necessary, we also offer a cutting or punching service after the rolling process.

Wide application possibilities and full technical support

Our rolling services are aimed at companies and designers who expect high manufacturing accuracy, short lead times and production flexibility. We prepare components for the production of silos, tanks, flue ducts, curved structures, interior design elements and many other applications. We support customers at every stage - from project analysis, through selection of the optimal technological solution, to implementation and delivery.

We carry out unit and serial orders - also for non-standard details or made of more difficult materials. With an experienced team and modern equipment, we are able to meet even the most demanding orders.

We carry out unit and serial orders - also for non-standard details or made of more difficult materials. With an experienced team and modern equipment, we are able to meet even the most demanding orders.

Sheet rolling supports tank, tube, and casing fabrication processes.

Realizations

ContactContact us

Rolling of sheets, pipes, profiles

FAQ

1. What materials can be rolled?

Structural steel, stainless steel, aluminum – in the form of sheets, tubes and closed profiles.

2. What shapes can be obtained by rolling?

Cylindrical, conical, curved, spiral parts – depending on the needs of the project.

3. Do you offer rolling of large-size elements?

Yes – we have rolling mills suitable for large sheets and thick plates.

4. Do you perform welding or further processing after rolling?

Yes – we can combine rolling with cutting, welding, assembly or painting.

5. Can I provide my own material for rolling?

Yes – we carry out orders on both our own and entrusted material.