What is laser welding and when is it worth using it?

Laser welding is a modern technology for joining materials, which makes it possible to achieve extremely precise, narrow and clean welds. Thanks to concentrated laser radiation, it is possible to join metals with minimal thermal effects on the surrounding material, reducing deformation and eliminating the need for further processing. At Metallbauform, we offer professional laser welding services for steel, stainless steel and aluminum components, both in unit and batch production.

This technology is particularly suitable for the precision industry - including electronics, medicine, automotive and tool manufacturing. It makes it possible to join very thin metal sheets, small parts and components requiring aesthetic and durable welds. The process is fast, clean, virtually splinter-free and ideal for projects requiring high repeatability.

This technology is particularly suitable for the precision industry - including electronics, medicine, automotive and tool manufacturing. It makes it possible to join very thin metal sheets, small parts and components requiring aesthetic and durable welds. The process is fast, clean, virtually splinter-free and ideal for projects requiring high repeatability.

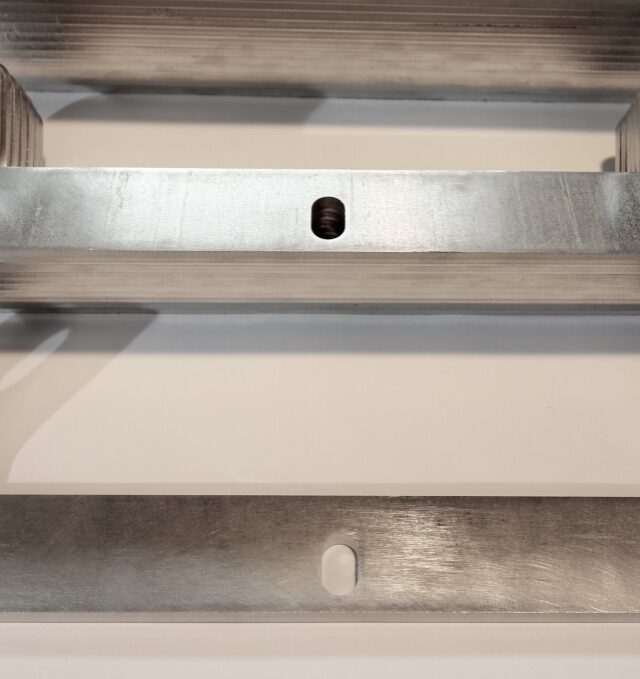

Laser welding ensures high accuracy and minimal thermal distortion.

We offer laser welding for fine-featured metal parts and tight assemblies.

Superior quality and state-of-the-art infrastructure

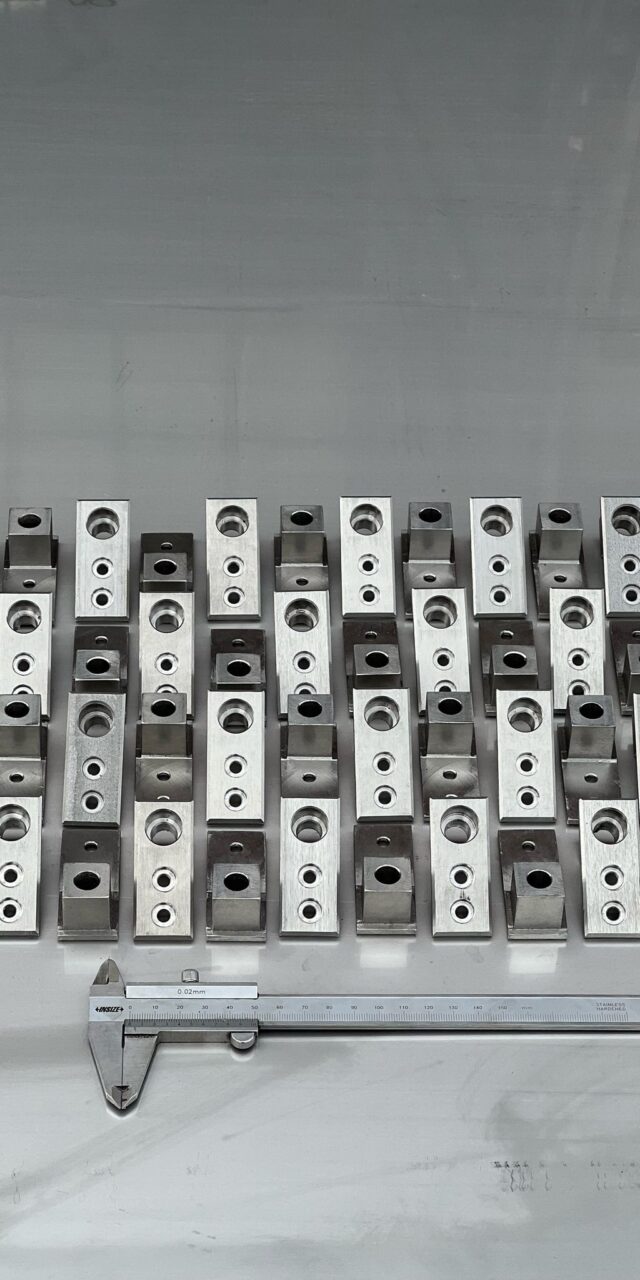

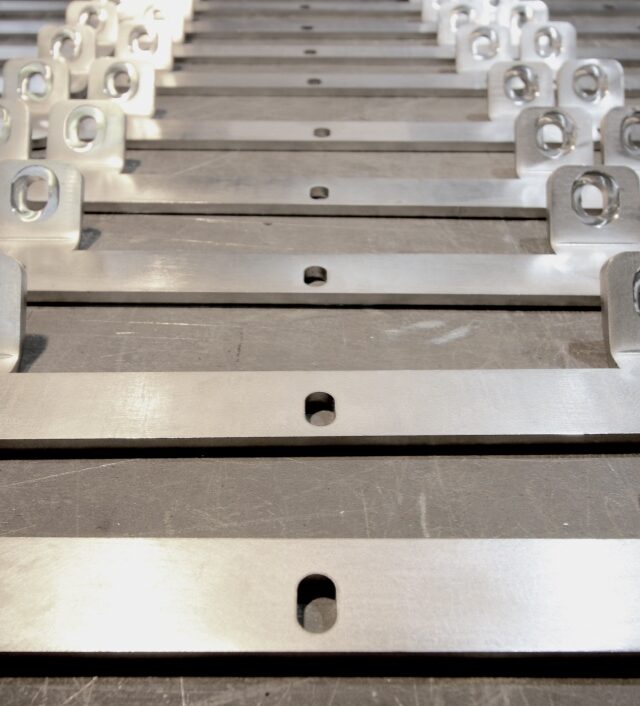

Our laser welding stations are equipped with high-precision laser sources and component positioning systems to achieve micrometer-level repeatability. Welding is carried out under controlled conditions, with minimal heat emission and no need for additional material, making the process very economical for large series. We use both spot and line laser welding - depending on the geometry and requirements of the project.

We offer full quality documentation, VT testing and, if necessary, destructive or non-destructive testing. The laser welding process is fully automated and monitored, guaranteeing consistently high quality regardless of the scale of production.

We offer full quality documentation, VT testing and, if necessary, destructive or non-destructive testing. The laser welding process is fully automated and monitored, guaranteeing consistently high quality regardless of the scale of production.

Versatile application and individual approach

We offer laser welding to customers in a wide range of industries, completing projects for precision structures, housing components, tools, structural details and other products requiring accuracy. We work with designers and engineers, offering assistance in optimizing details for this technology. Thanks to low thermal interference, the laser is also ideal for joining materials of different thicknesses.

We provide a flexible approach to each order - from consultation and analysis of technical documentation, through the selection of parameters, to the finished product. Laser welds meet aesthetic, technical and sanitary standards - often without the need for additional grinding or post-processing.

We provide a flexible approach to each order - from consultation and analysis of technical documentation, through the selection of parameters, to the finished product. Laser welds meet aesthetic, technical and sanitary standards - often without the need for additional grinding or post-processing.

Laser welding is used in electronics, medical devices, and precision optics.

Realizations

Contact Contact us

Laser welding

FAQ

1. What materials can be laser welded?

Stainless steel, aluminum, structural steel and some non-ferrous metal alloys – including thin-walled parts.

2. Do laser welds require further processing?

Usually not – they are very aesthetically pleasing, clean and accurate. In many cases, they do not need to be ground or masked.

3. Is it possible to weld parts of very small dimensions?

Yes – the laser allows you to join micro-separated details and thin sheets with high accuracy.

4. Do you perform welds in large series?

Of course – laser welding is ideal for mass production, including automated versions.

5. Is it possible to realize test or trial welding at your company?

Yes – we offer to make a test weld, analyze the quality and verify it for later series production.