Application of laser cutting in modern manufacturing

Laser cutting is currently one of the most accurate and versatile methods of dividing metals and other technical materials. Thanks to the concentrated laser beam, it is possible to precisely cut parts of any shape without the need for additional edge finishing. At Metallbauform, we offer laser cutting services for steel, stainless steel and aluminum sheets of various thicknesses, guaranteeing high repeatability and compliance with the technical drawing.

This technology works well for both single components and large production runs - for the industrial, construction, furniture, advertising and many other industries. We also offer laser cutting for individual customers and designers who expect high aesthetics and dimensional precision.

This technology works well for both single components and large production runs - for the industrial, construction, furniture, advertising and many other industries. We also offer laser cutting for individual customers and designers who expect high aesthetics and dimensional precision.

Our laser cutting machines handle thin and thick sheets with high precision.

Laser cutting is ideal for prototyping, signage, and complex part design.

Machine park and cutting process control

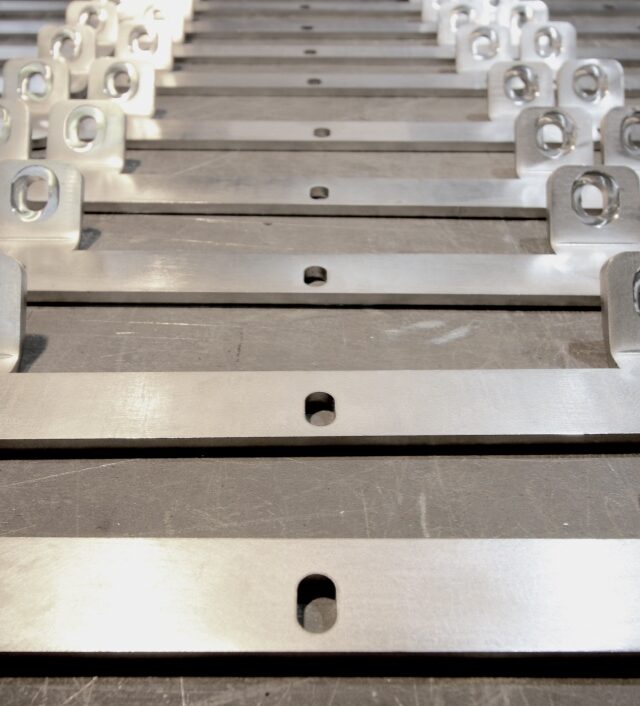

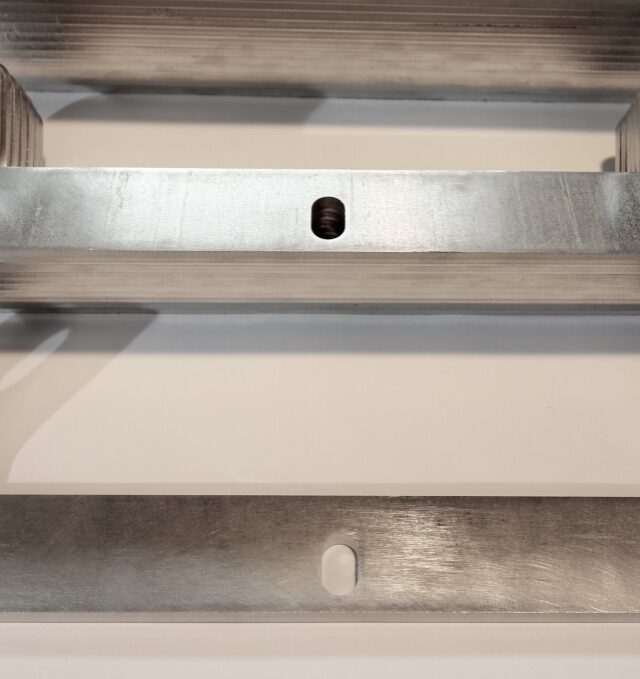

We have modern high-powered CO₂ and fiber lasers that can cut sheet metal from 0.5 mm to several millimeters thick. Thanks to automatic feeders, positioning systems and large-format working tables, we can realize even the most demanding orders in a short time. The cutting process is computer-controlled on the basis of CAD/CAM files, which ensures full repeatability and no errors resulting from manual processing.

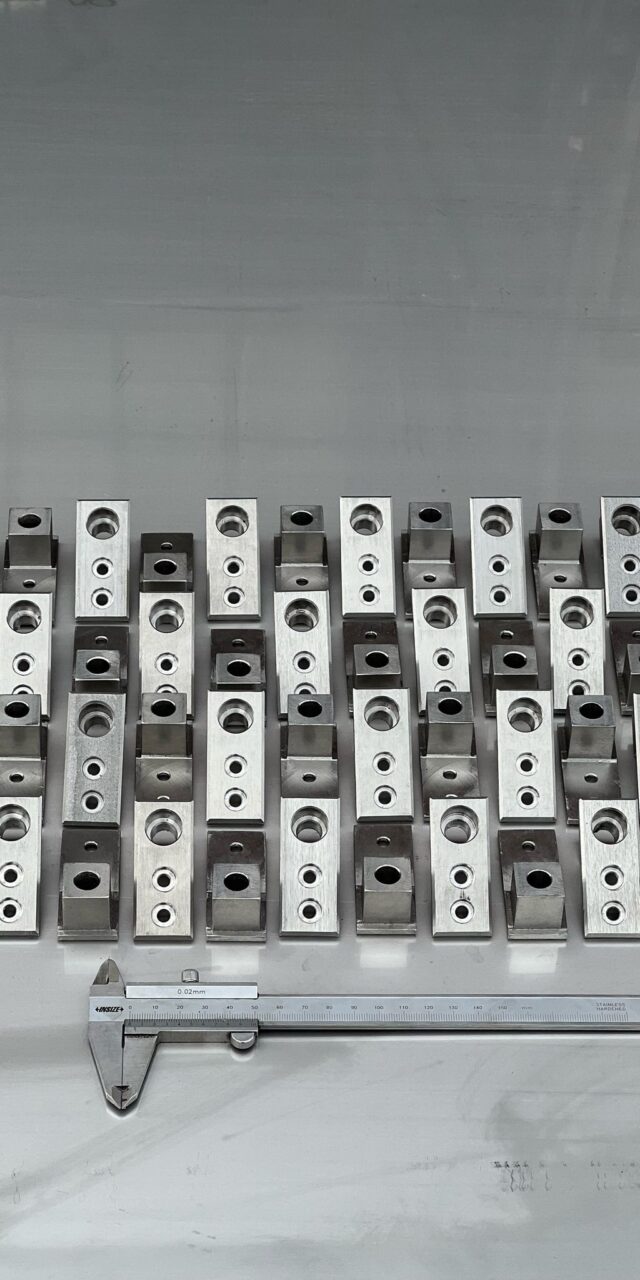

All parts undergo quality control - we check dimensional accuracy, edge quality and compliance with the design. Finished parts can be marked, labeled or prepared for further production stages (e.g. bending, welding, painting).

All parts undergo quality control - we check dimensional accuracy, edge quality and compliance with the design. Finished parts can be marked, labeled or prepared for further production stages (e.g. bending, welding, painting).

Flexibility and full technical support

We offer comprehensive service - from project preparation, through technological consulting, to the implementation of cutting and delivery of finished components. We handle unit orders, short series and high volume production. For more complex projects, we help optimize the geometry of components to reduce material waste and production time.

Our approach is characterized by flexibility, timeliness and commitment - we know the importance of detail and quality workmanship in modern industry. Regardless of the scale of the order, we provide full support and high precision workmanship.

Our approach is characterized by flexibility, timeliness and commitment - we know the importance of detail and quality workmanship in modern industry. Regardless of the scale of the order, we provide full support and high precision workmanship.

Laser cutting provides sharp edges and exact part contours with low waste.

Realizations

ContactContact us

Laser cutting

FAQ

1. What materials can be laser cut?

Black steel, stainless steel, aluminum – as well as selected engineering plastics (on request).

2. What sheet thicknesses do you handle?

From 0.5 mm to 20 mm – depending on the material and the type of laser.

3. Can you make a cut from my file?

Yes – we accept DXF, DWG, STEP, PDF files. We can also prepare a file based on a sketch.

4. Do you also offer further processing after cutting?

Yes – bending, welding, powder coating, assembly. We provide comprehensive services.