What is metal bending and what possibilities does it offer?

Bending is one of the most efficient methods of metal forming. It makes it possible to change the shape of a component without removing parts of it, thus preserving its integrity and strength. At Metallbauform, we offer comprehensive bending services for sheet metal, bars and profiles using modern CNC press brakes and specialized tube and profile bending machines. We handle orders from a wide range of industries - from industry to furniture to modern architecture.

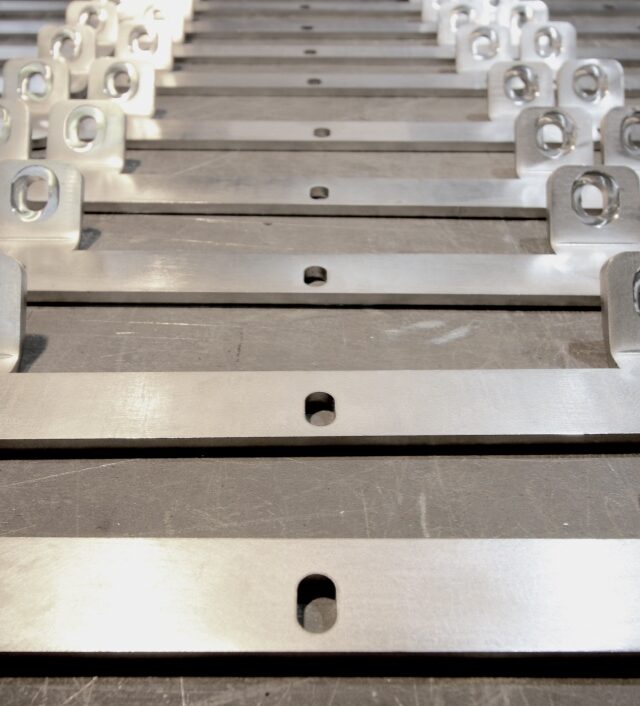

Thanks to the precision of numerical control, we are able to produce bends with precise angles, radii and repeatability, even with complex geometries. It's ideal for manufacturing enclosures, brackets, boxes, roof flashings, supports or decorative elements. Bending is also a great alternative to welding - especially for thin-walled materials.

Thanks to the precision of numerical control, we are able to produce bends with precise angles, radii and repeatability, even with complex geometries. It's ideal for manufacturing enclosures, brackets, boxes, roof flashings, supports or decorative elements. Bending is also a great alternative to welding - especially for thin-walled materials.

Sheet bending produces accurate angles for enclosures, panels, and frames.

We offer CNC sheet bending for repeatable and dimensionally accurate results.

Machine park and control of bending parameters

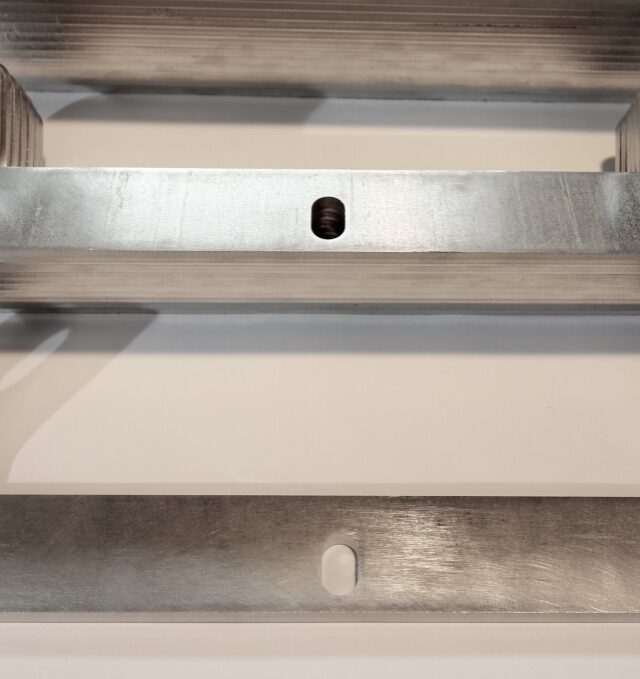

We have high-pressure press brakes that allow us to bend sheets of various thicknesses - from thin (0.8 mm) to thicker sheets (up to 10 mm). Bending takes place without the effect of cracks, kinks or loss of flatness, thanks to precise pressure control, suitable dies and modern control systems. For pipes and profiles, we use roller and mandrel benders, which allow us to form elements into arcs, spirals or angles.

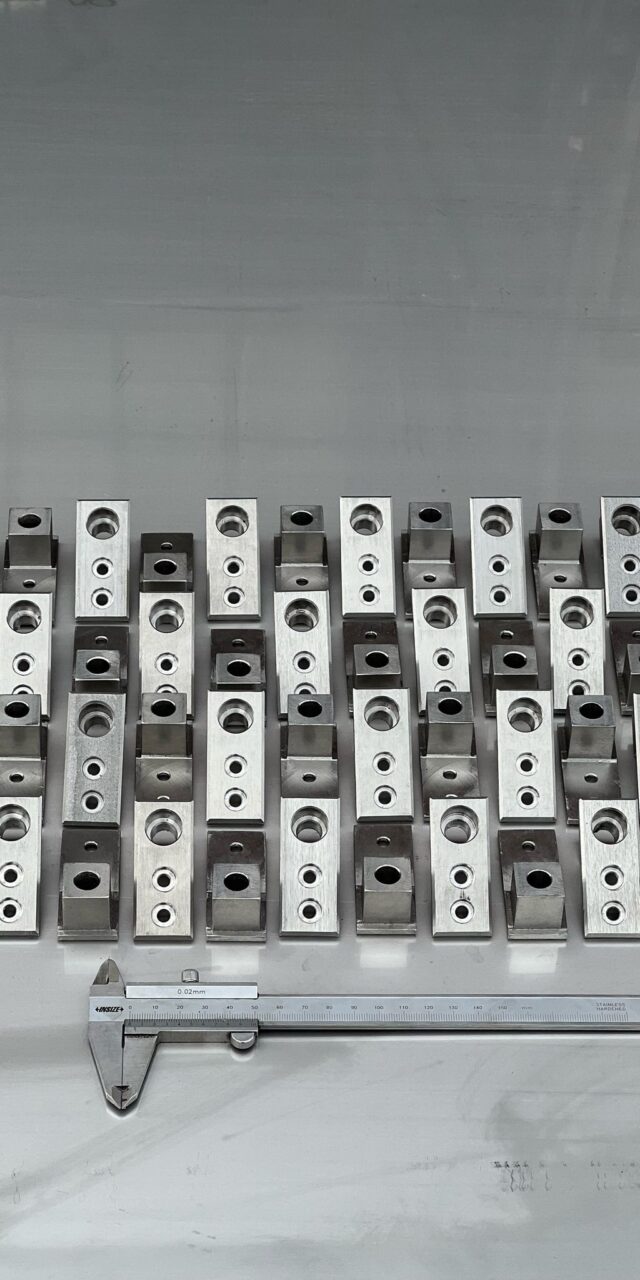

Each order is individually analyzed - we select the technology for the material, its thickness and the expected shape. Finished parts are accurately measured and safely packaged, ready for further assembly or processing.

Each order is individually analyzed - we select the technology for the material, its thickness and the expected shape. Finished parts are accurately measured and safely packaged, ready for further assembly or processing.

Universal application and individual approach to projects

Bending is a process that is used in almost every industry - from construction and installation to the food industry and interior decoration. We realize both simple bends and details with complex geometries. We support customers at every stage of implementation - from construction consulting, through the development of technical files, to the manufacture and delivery of finished parts.

We handle serial, prototype and unit orders - ensuring timeliness, high quality and a flexible approach. Thanks to our experience, metal bending becomes a fast, efficient and economical process - fully tailored to the customer's needs.

We handle serial, prototype and unit orders - ensuring timeliness, high quality and a flexible approach. Thanks to our experience, metal bending becomes a fast, efficient and economical process - fully tailored to the customer's needs.

Sheet bending allows for fast processing of aluminum, steel, and stainless parts.

Realizations

ContactContact us

Bending of sheets, bars, profiles

FAQ

1. What materials can be bent?

Black steel, stainless steel, aluminum – in the form of sheets, tubes, hollow sections and bars.

2. What sheet thicknesses do you handle?

Standard bending up to 10 mm thick. For larger sheets – the possibility of individual consultation.

3. Do you offer bending of tubes and profiles into curves?

Yes – we have bending machines for pipes and profiles, which allow bending in different planes and radii.

4. Can I provide my own material?

Of course – we perform bending on both our own and entrusted material.

5. Do you help in the preparation of technical documentation?

Yes – we can prepare drawings, CAM files or advise on the best solution for your project.