Industrial welding - joining materials with guaranteed quality

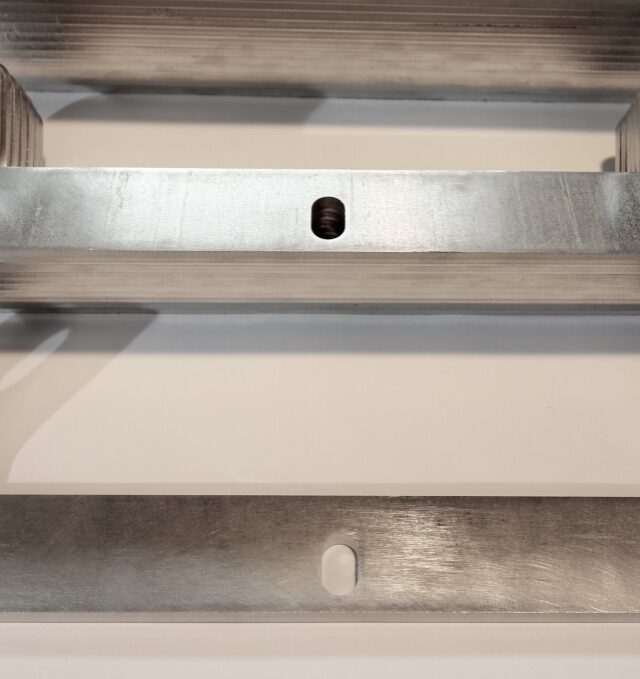

We carry out each order with attention to the quality of welds, compliance with documentation and safety of use. We work in accordance with PN-EN ISO 3834 standards and provide full quality control - including visual and penetrant testing and documentation of welds. We serve customers in the industrial, construction, technology and installation industries.

Welding and plastic machining are essential services for creating durable and functional components.

Our welding and plastic machining solutions meet high standards for strength, precision, and repeatability.

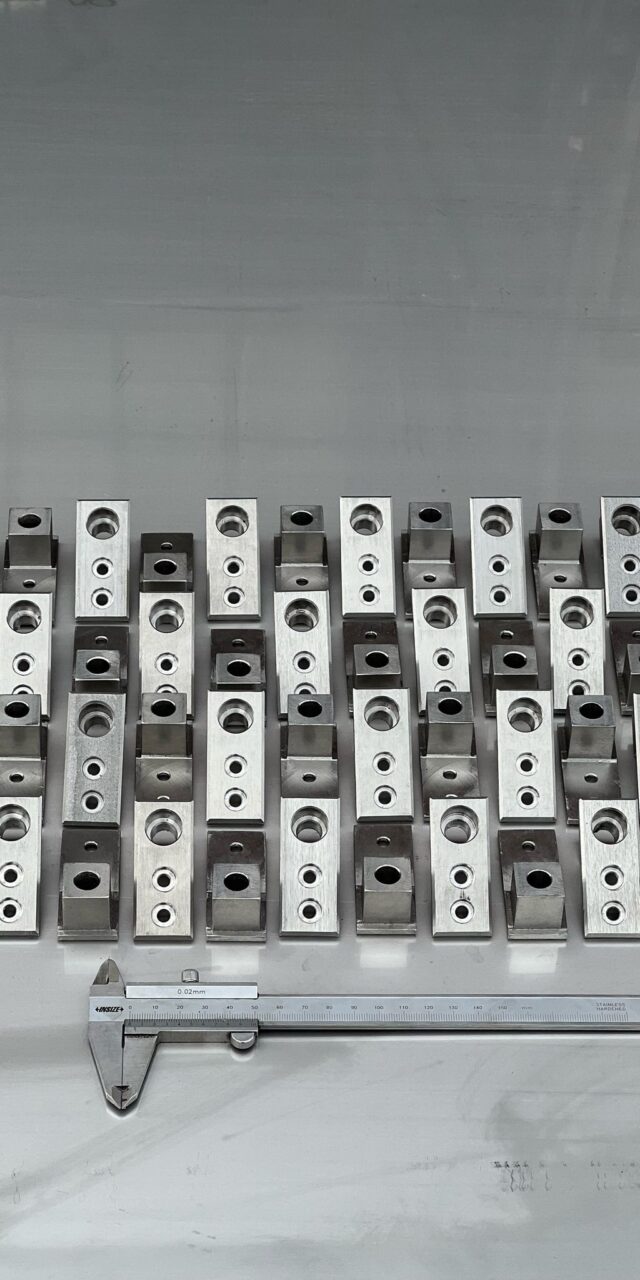

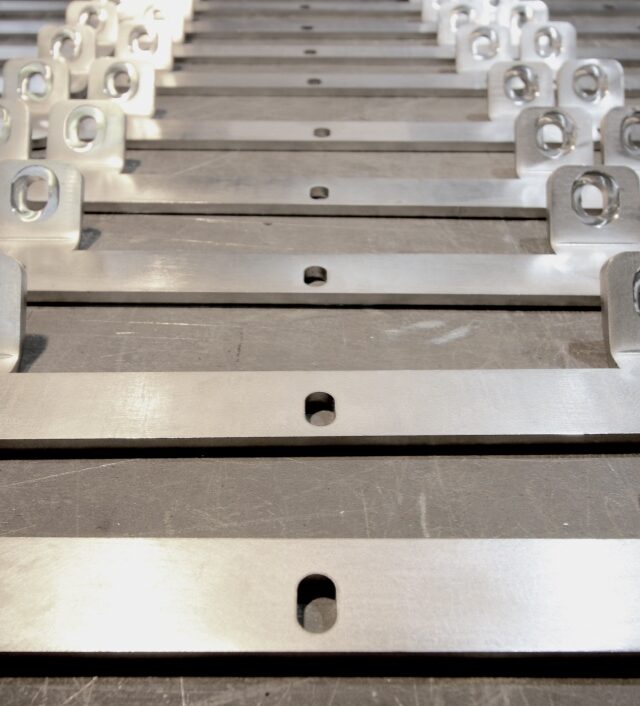

Metal forming - precision forming of metal without loss of properties

Thanks to modern CNC press brakes and rolling mills, we are able to form parts with high precision and repeatability. We tailor each project individually to the type of material, thickness and shape of the part. Forming allows us to significantly reduce production time and waste, which is why it is so readily used in the serial production of components.

Comprehensive implementation of metal projects - from A to Z

We carry out orders for load-bearing structures, machine housings, installation components, frames, brackets and many others. We serve investors from all over Poland, and our products meet all quality and technical standards. We ensure timeliness, transparency of cooperation and full commitment.

With advanced tools, we deliver welding and plastic machining tailored to industrial applications.

Realizations

ContactContact us

Welding and metal forming

FAQ

We weld with TIG, MIG/MAG methods. The choice of method depends on the type of material and project requirements.

Yes – we offer documentation in accordance with ISO 3834, VT, PT testing, as well as material certificates and WPS procedures.

Black steel, stainless steel, aluminum – in the form of sheets, bars, tubes and profiles. We select the technology individually.

Yes – for larger projects we offer assembly of structures at the customer’s site, along with the necessary equipment and personnel.

Of course – we also carry out small unit projects and custom orders.