Designing components for machines, structures and utility products

At Metallbauform, we design customized metal, steel and plastic components. We create both simple technical details and complex structural, mechanical and decorative components. We serve manufacturing, design and technology companies, as well as individual customers who need precise, functional solutions ready for implementation.

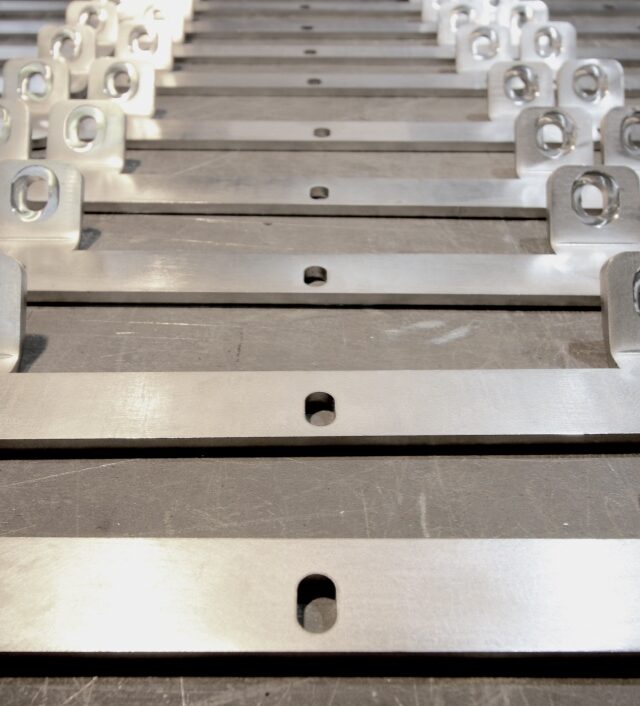

Our projects include, among others, housings, handles, guides, fasteners, cover components, mechanisms or details for process lines. With advanced 3D software, we create CAD models that can be directly transferred to CNC machining, laser cutting or 3D printing - depending on the material and manufacturing technology.

Our projects include, among others, housings, handles, guides, fasteners, cover components, mechanisms or details for process lines. With advanced 3D software, we create CAD models that can be directly transferred to CNC machining, laser cutting or 3D printing - depending on the material and manufacturing technology.

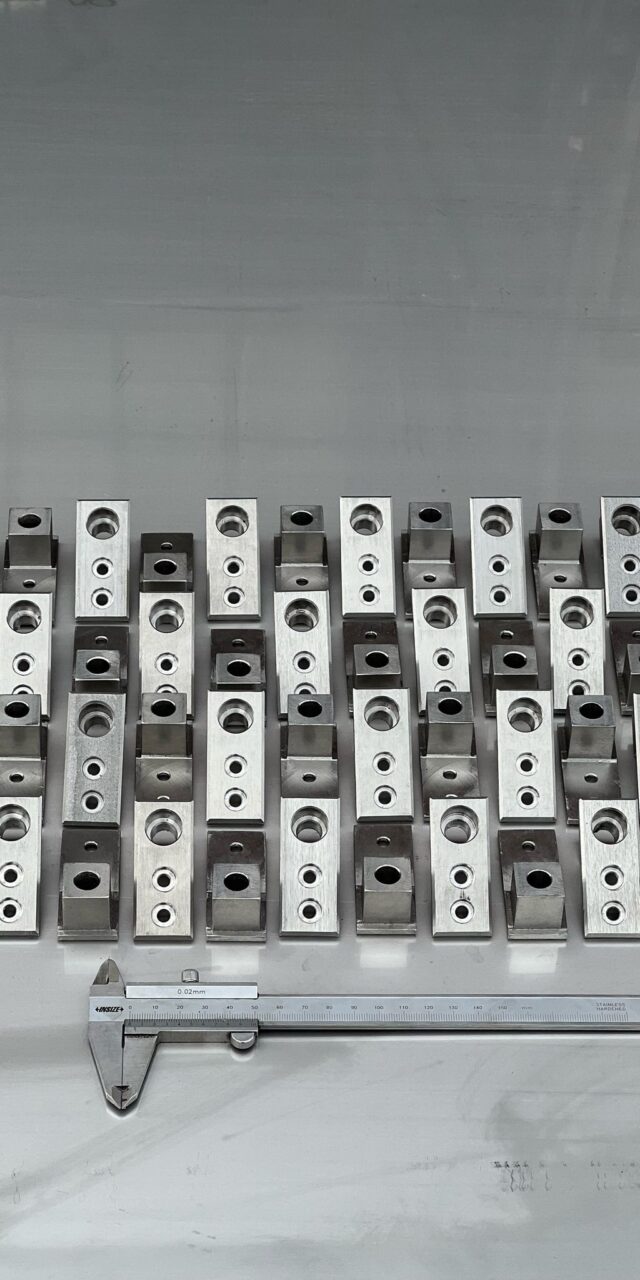

Metal component design for mass manufacturing, tooling, and high-stress use.

We deliver metal component design that ensures functionality and processability.

Flexible cooperation and full technical support

Whether you have a ready-made concept or are just starting out, we support you at every stage - from idea to implementation. We can create a design based on a sketch, description or technical conversation. We work with engineers, designers and manufacturers, tailoring the documentation to the specific requirements of CAM systems or your production standards.

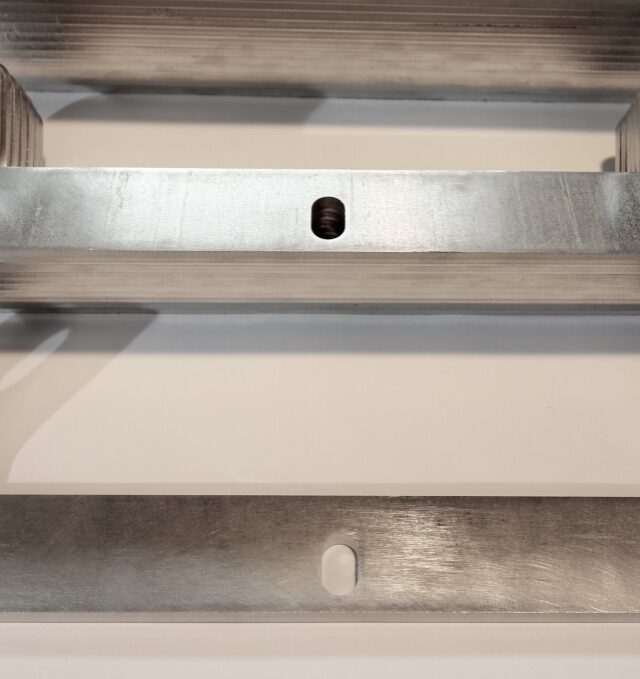

We complete orders in a timely manner, ensuring high quality, legibility of drawings and compliance with documentation. We also offer support in implementing the design into the further process - including the possibility of making a sample or test piece.

We complete orders in a timely manner, ensuring high quality, legibility of drawings and compliance with documentation. We also offer support in implementing the design into the further process - including the possibility of making a sample or test piece.

Elastyczna współpraca i pełne wsparcie techniczne

Niezależnie od tego, czy masz gotową koncepcję, czy dopiero zaczynasz, wspieramy Cię na każdym etapie – od pomysłu po realizację. Możemy stworzyć projekt na podstawie szkicu, opisu lub rozmowy technicznej. Współpracujemy z inżynierami, projektantami i producentami, dostosowując dokumentację do konkretnych wymagań systemów CAM lub standardów Twojej produkcji.

Zlecenia realizujemy terminowo, dbając o wysoką jakość, czytelność rysunków i zgodność z dokumentacją. Oferujemy także wsparcie przy wdrażaniu projektu do dalszego procesu – w tym również możliwość wykonania próbki lub elementu testowego.

Zlecenia realizujemy terminowo, dbając o wysoką jakość, czytelność rysunków i zgodność z dokumentacją. Oferujemy także wsparcie przy wdrażaniu projektu do dalszego procesu – w tym również możliwość wykonania próbki lub elementu testowego.

Metal component design focused on strength, geometry, and ease of assembly.

Realizations

ContactContact us

Metal component design

FAQ

1. What types of components do you design?

Enclosures, fasteners, guides, handles, machine details, fastening elements – customized according to individual customer needs.

2. Do you carry out projects made of plastics?

Yes – we also design elements from POM, PC, PVC, PE and other technical materials.

3. Is it possible to make only one copy (prototype)?

Yes – we realize prototypes and single test pieces, which can then be put into production.

4. In what programs do you prepare designs?

We use 2D/3D CAD software (e.g. SolidWorks, Inventor), compatible with most CAM systems.

5. Can I receive the design in STEP/DXF/PDF format?

Yes – we provide files in the required production and visualization formats.