Ideal CNC machining for demanding materials

Stainless steel is a demanding material - hard, corrosion-resistant and difficult to machine. Turning stainless steel requires the right experience, tools and machining parameters. At Metallbauform, we offer professional CNC turning services for stainless steel - whether for the food and pharmaceutical industries, heavy industry or machinery manufacturers.

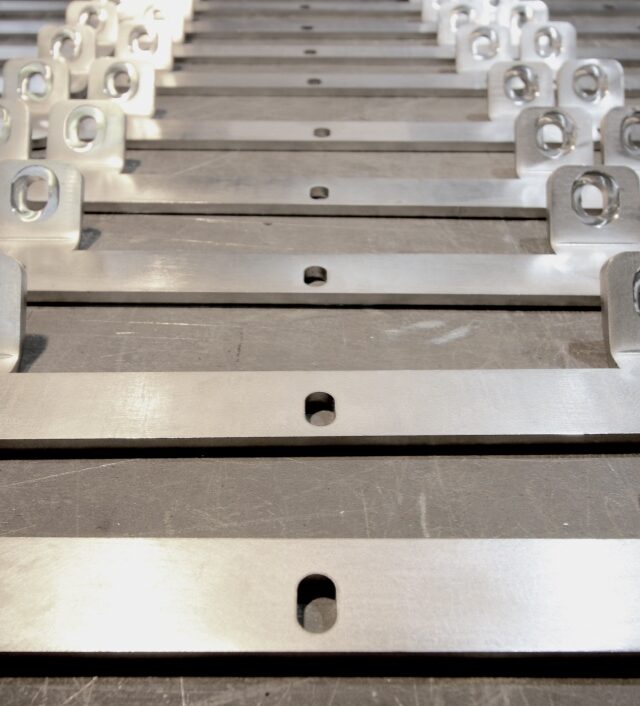

We turn parts such as shafts, bushings, bodies, joints, rings and other machined parts from AISI 304, 316, 321 and similar grades. We fulfill orders from single pieces to thousandths series.

We turn parts such as shafts, bushings, bodies, joints, rings and other machined parts from AISI 304, 316, 321 and similar grades. We fulfill orders from single pieces to thousandths series.

Stainless steel turning provides hygienic, polished, and corrosion-proof parts.

We perform stainless steel turning for food, medical, and water systems.

Advanced machinery and precision control

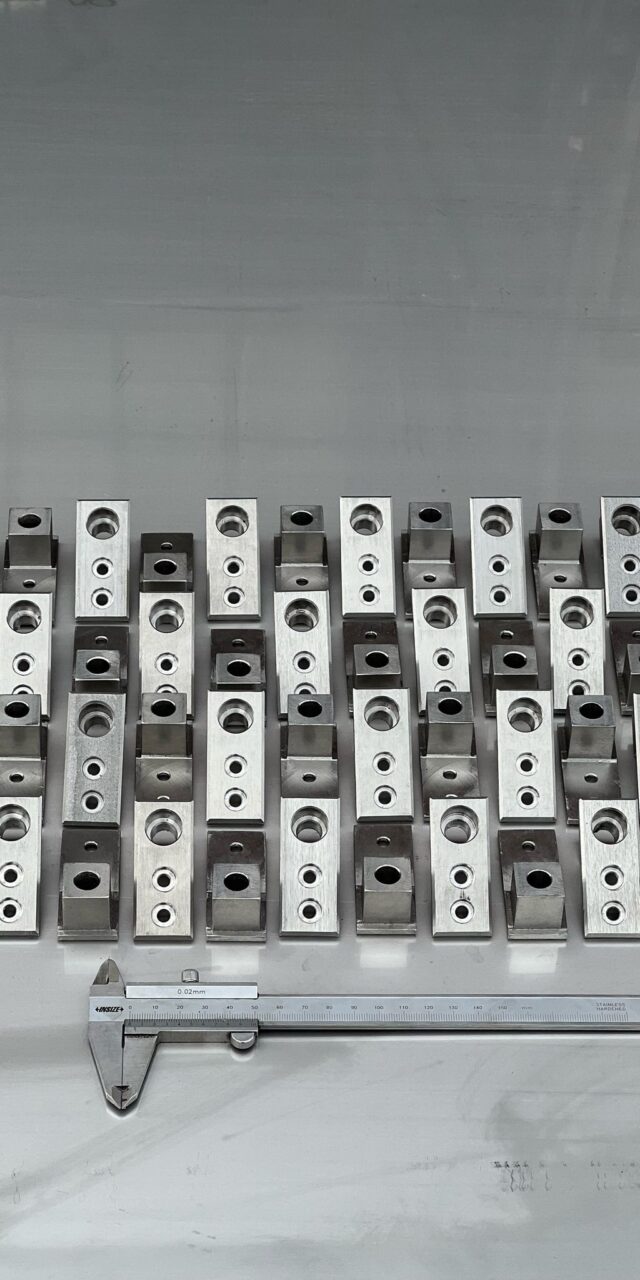

We work on modern CNC turning centers with tool cooling and automatic material feeding systems. Each part undergoes strict quality control - we measure dimensionality, check for conformance to the drawing, and analyze the surface for micro-damage. We also offer measurement documentation and material certificates upon request.

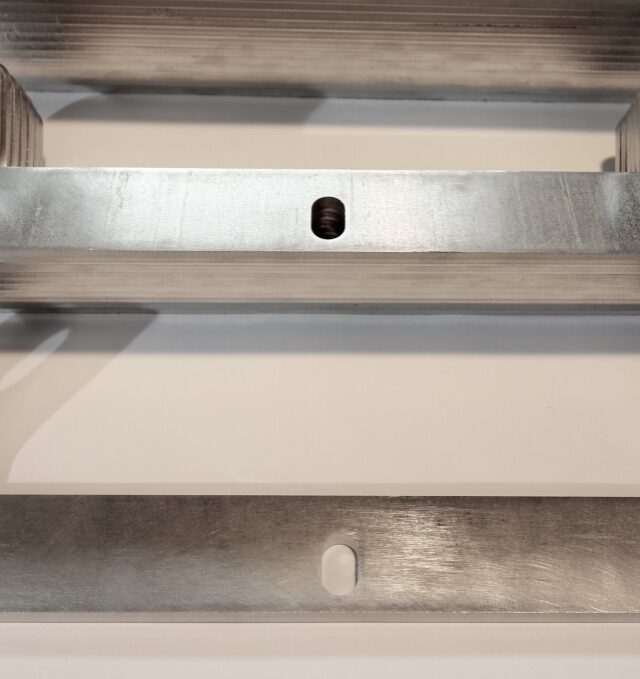

We perform the processing taking into account the parameters of the steel grade to avoid overheating, deformation and overgrowth. This guarantees high final quality and compliance with the requirements of industry standards.

We perform the processing taking into account the parameters of the steel grade to avoid overheating, deformation and overgrowth. This guarantees high final quality and compliance with the requirements of industry standards.

Flexible terms of cooperation and fast implementation

We support customers at every stage - from the preparation of the drawing, through the selection of material, to the delivery of finished parts. We fulfill orders for manufacturers of machinery, transportation systems, medical devices and industrial structures. Thanks to the experience of our technologists, we can optimize projects in terms of cost and processing efficiency.

We execute orders efficiently and on time, providing professional service and a flexible approach to the customer. We pack the finished parts with care for safety during transportation.

We execute orders efficiently and on time, providing professional service and a flexible approach to the customer. We pack the finished parts with care for safety during transportation.

Stainless steel turning ensures quality surfaces and reliable dimensions.

Realizations

ContactContact us

Turning of stainless steel

FAQ

1. What grades of stainless steel do you machine?

Mostly: AISI 304, 316, 316Ti, 321 – but we also realize others on special order.

2. Do you also make measurement documentation?

Yes – we offer measurement reports, certificates of conformity and material traceability.

3. Can I order a short series or prototype?

Of course – we realize from single pieces to large series. We also specialize in non-standard details.

4. What kind of accuracy do you achieve when turning stainless steel?

In most cases ±0.01 mm, but for precision projects we go even lower – according to the standard.

5. Do you also offer surface finishes?

Yes – brushing, polishing, passivation and other forms of finishing.