The versatility of plastics turning in industry and prototype manufacturing

We machine, among others, POM (Acetal), PA (polyamide), PTFE (Teflon), PC (polycarbonate), PMMA (Plexiglas), PE, as well as specialty engineering plastics. Our services are used in the production of machine components, guides, gears, bushings, insulators and components for the food, medical and chemical industries. Thanks to CNC technology, we are able to achieve accuracies of hundredths of a millimeter.

Plastics turning for dimensionally stable and chemically resistant components.

We offer plastics turning for parts that need electrical insulation or low weight.

A modern approach to turning lightweight materials

Thanks to our experience, we can machine plastics with different properties - from soft to high-strength - depending on the needs of a given project. We also offer additional operations such as drilling, threading, groove cutting and final grinding. In the case of optical or transparent parts (e.g., Plexiglas), we take exceptional care to achieve an aesthetically pleasing end result.

Individual approach and full technical support

Finished parts are thoroughly cleaned, packaged and labeled according to your requirements. We operate flexibly - we adapt to your production schedules and industry standards. With our knowledge and technological background, you can be sure that even the most demanding projects will be completed with due care.

Plastics turning is ideal for non-metal applications with precise tolerances.

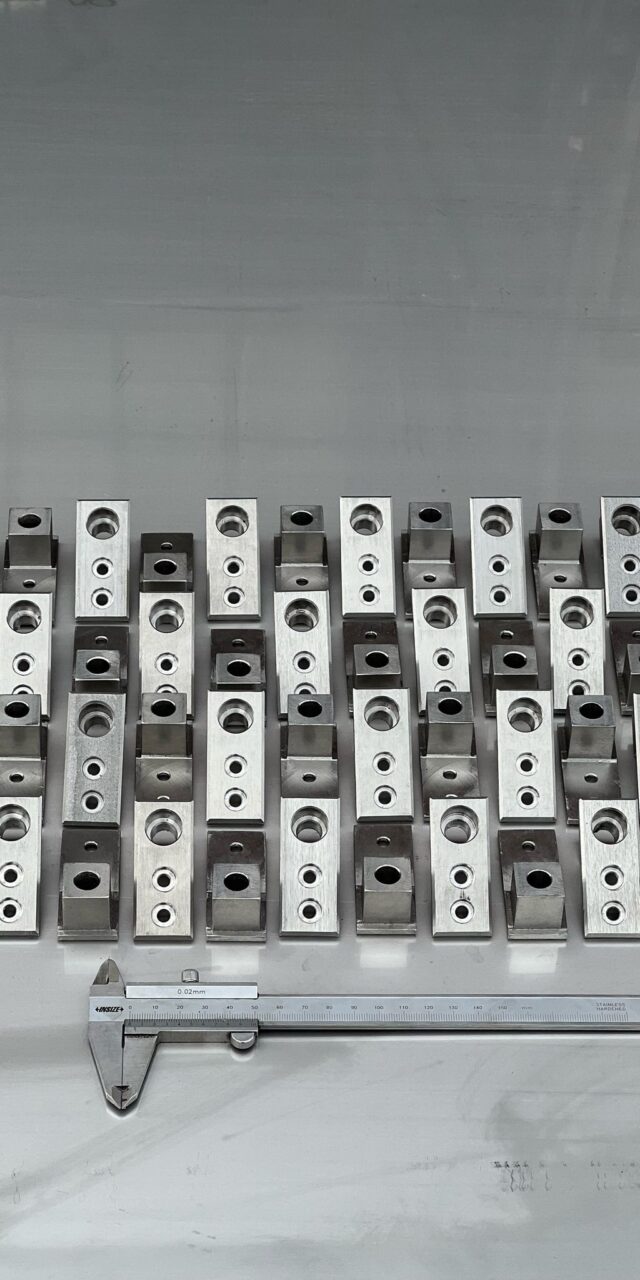

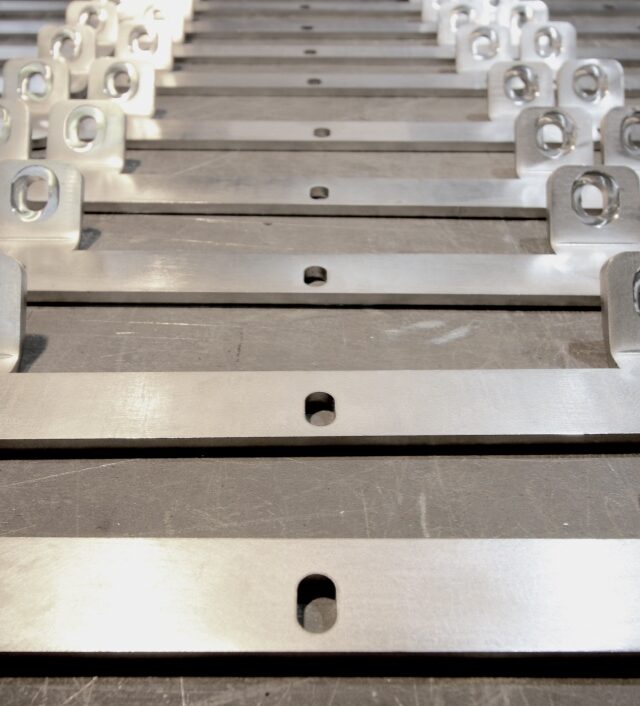

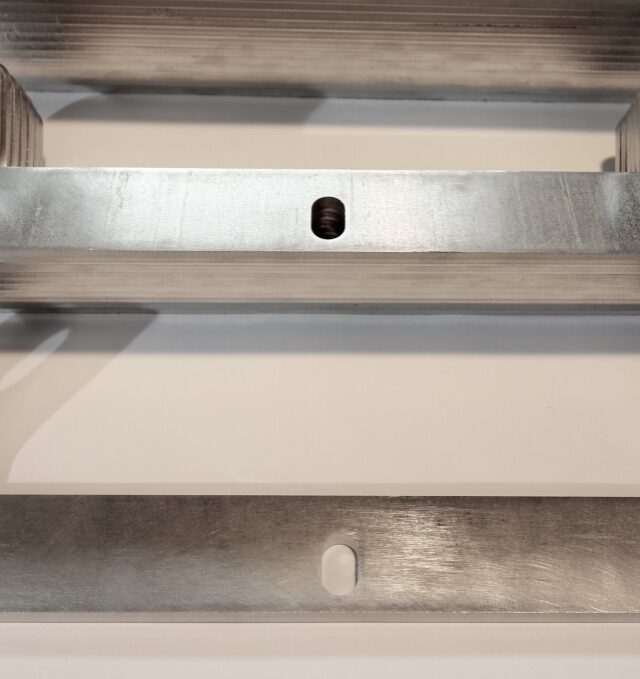

Realizations

ContactContact us

Turning plastics

FAQ

We turn POM, PA6, PTFE, PC, PMMA, PE and other engineering and technical plastics, among others. The choice of material depends on the application and working conditions of the component.

Yes – we realize both single pieces and short trial series. This is ideal for builders and designers.

If the customer does not have a ready file, we help prepare technological documentation in CAM/CAD formats.

The surface is smooth, free of burn marks and imperfections. For transparent materials, additional polishing is possible.

Yes – we are experienced in working with plastics approved for food contact and requiring hygienic approvals.