Universal metal turning - steel, aluminum, brass and other materials

Our workpieces go to industries such as machine building, energy, automotive, plumbing, as well as the furniture and design sectors. We realize the turning of both technical elements (shafts, bushings, pins) and aesthetics (housings, rings, structural details). Thanks to CNC precision, we guarantee high product quality, regardless of batch size.

Metal turning for durable components in automotive, marine, and energy sectors.

We perform metal turning on high-strength alloys with strict tolerances.

Advanced technology and quality control at every stage

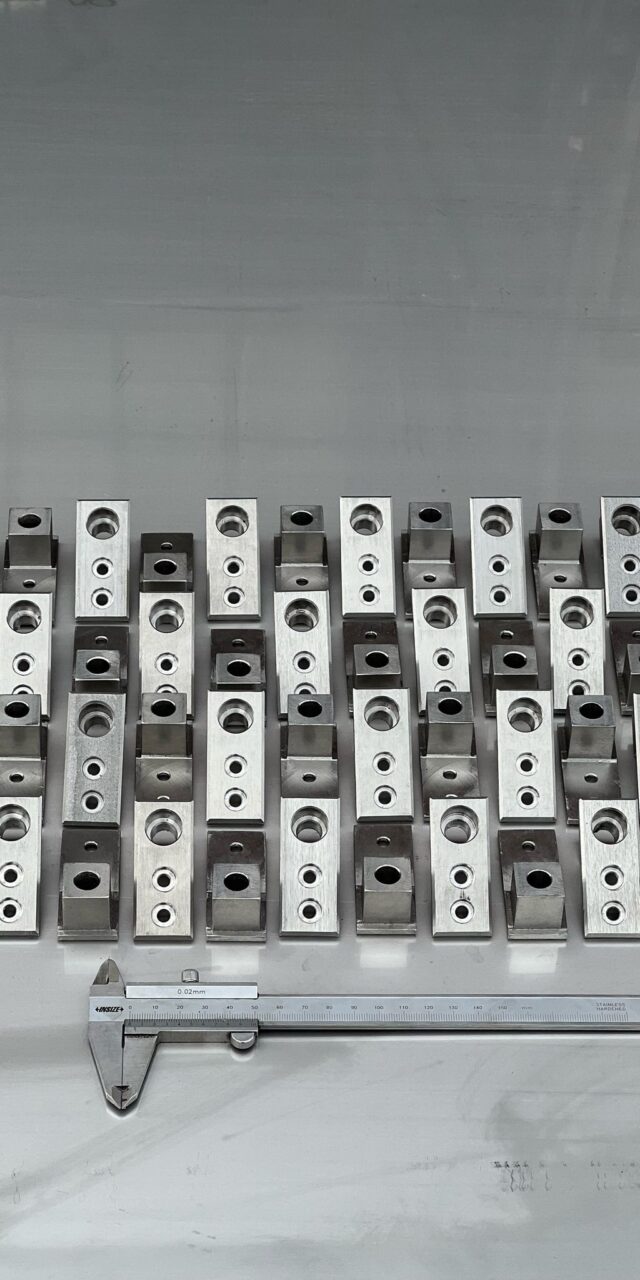

Each component undergoes quality control - both dimensional (measured with precision tools) and visual. For more demanding customers, we also offer measurement documentation and declarations of conformity. We work in accordance with ISO and PN-EN standards.

Full support and flexible execution of orders

We offer competitive terms, short lead times and the ability to handle unit, prototype and serial orders. We package finished parts according to customer requirements - ready for further assembly or distribution.

Metal turning is ideal for high-load and wear-resistant mechanical parts.

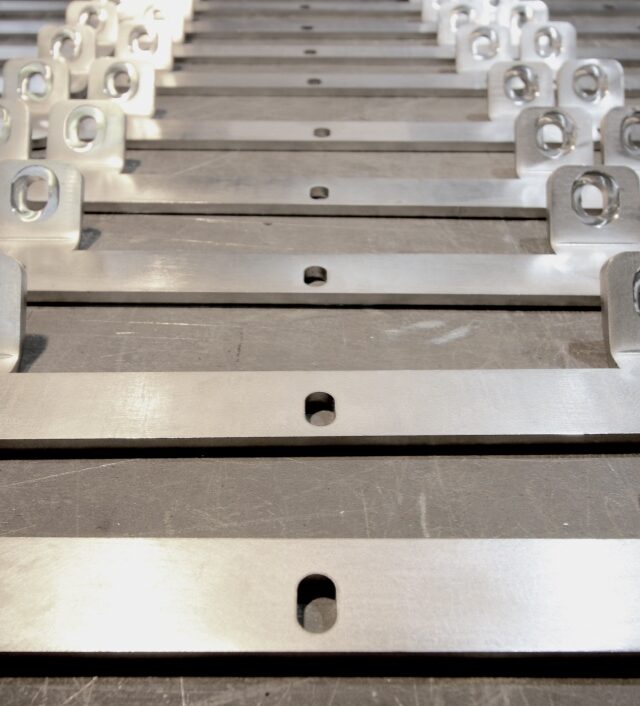

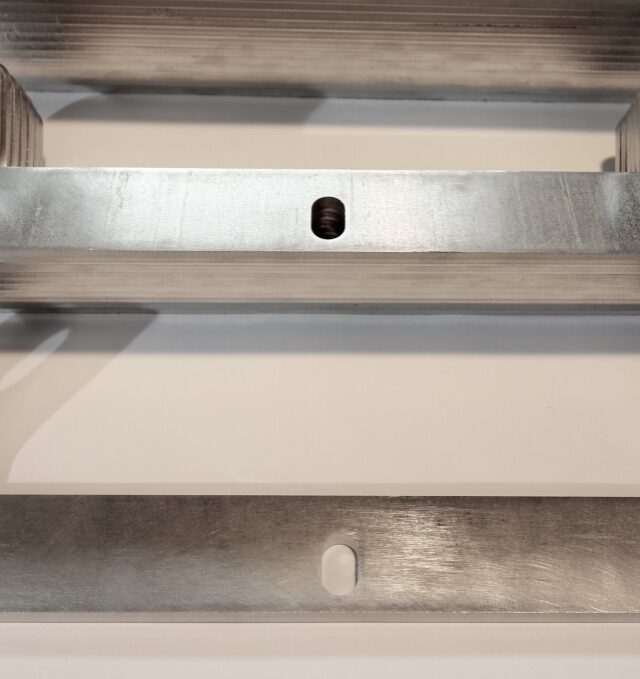

Realizations

ContactContact us

Metal turningFAQ

We turn black steel (S235, S355), stainless steel (AISI 304/316), aluminum, brass, bronze, copper and plastics.

Yes – we specialize in flexible production. For short series, we offer quick implementation and assistance in optimizing the design.

We machine workpieces up to a diameter of 300 mm and a length of 1000 mm – depending on the type of machine and the complexity of the project.

Yes – including threading, grooving, grinding, as well as combining turning with milling.

Just send a CAD file or a drawing – we will take care of the quotation, preparation of technology, production and delivery of the finished product.