Why bet on aluminum turning?

We serve customers in industries such as automotive, electronics, transportation systems, furniture, light structures and the visual advertising sector. Our solutions also work well for prototypes and custom projects where accuracy and aesthetics matter. Aluminum is a material that requires a special approach - but with the right turning parameters, it makes it possible to achieve an exceptional end result.

Aluminum turning for lightweight parts requiring high speed and low friction.

We use aluminum turning for motor components, enclosures, and connectors.

Modern machinery and experience in aluminum turning

Depending on the project, we perform external turning, internal turning, axial drilling, grooving and threading - all in one cycle, without the need to rearrange the workpiece. We can machine both bars and semi-finished parts with larger diameters and lengths. Parts after machining are thoroughly cleaned, packaged and prepared for further assembly, anodizing or final assembly. For customers looking for high quality and aesthetics - CNC aluminum turning is the ideal solution.

Flexible approach and full technical support for your project

We realize both rapid prototypes and complex production series - adjusting the schedule to your needs. We deliver finished parts in a protected manner, marked according to the design and ready to be implemented in the further production process. We operate on time, flexibly and without unnecessary delays - because we know that it is not only quality, but also time that matters to our customers.

Aluminum turning produces corrosion-resistant parts with minimal secondary operations.

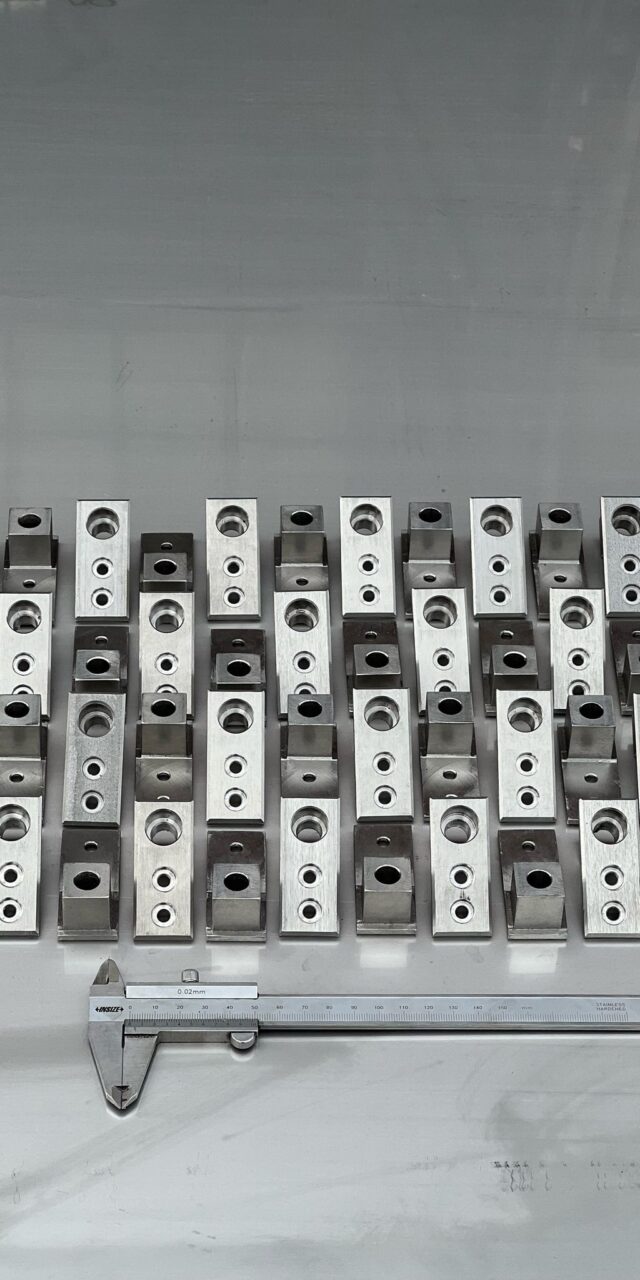

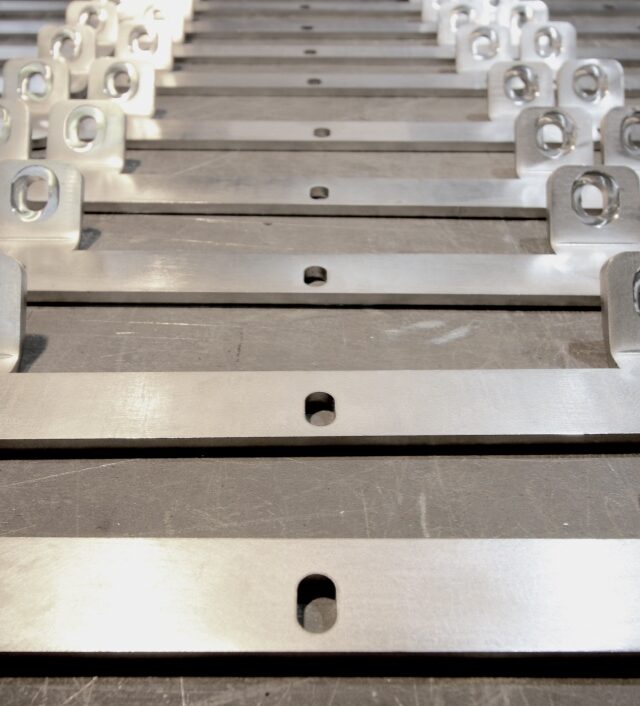

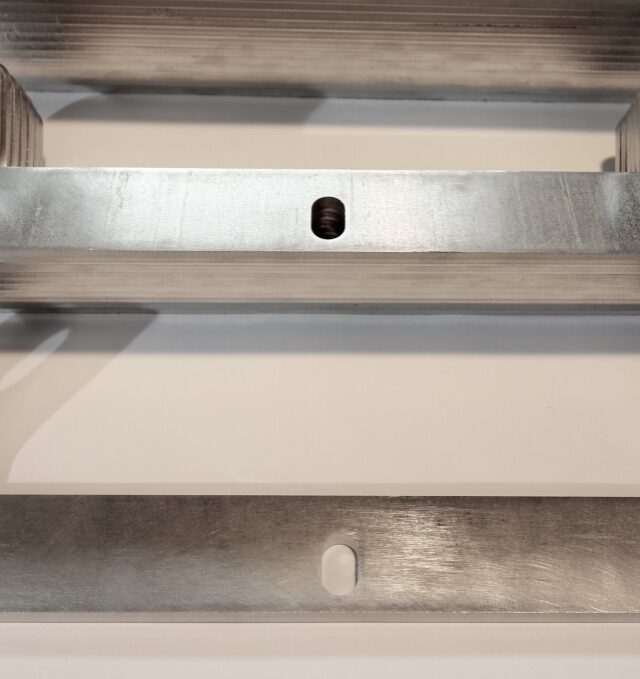

Realizations

ContactContact us

Turning of aluminumFAQ

Most often we machine aluminum 6000 series – 6060, 6082, as well as softer grades of 1000 and 2000 series. The choice of material depends on the purpose of the workpiece and the required hardness and strength.

Yes, on request we can combine turning with milling of parts – for example, making flat surfaces, cross holes or mounting grooves.

Of course – all you need is a sketch or description, and our specialists will prepare a CAM file and optimize the production technology.

Depending on the type of machine tool, we can machine parts up to a diameter of 300 mm and a length of 1000 mm. For larger projects – please consult us.

Yes – we work with partners for anodizing, brushing and polishing of aluminum. We can provide a component ready for final assembly.