Milling of structural, tool and alloy steel

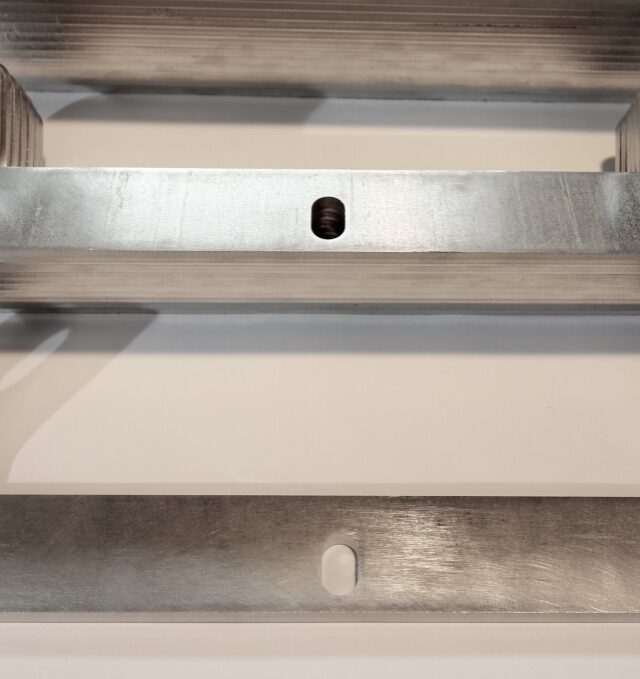

We machine parts of varying degrees of complexity - from simple shapes to parts with complex spatial geometry. Steel as a material requires appropriate cutting parameters and selection of tools - in this regard we offer full technical support and advice.

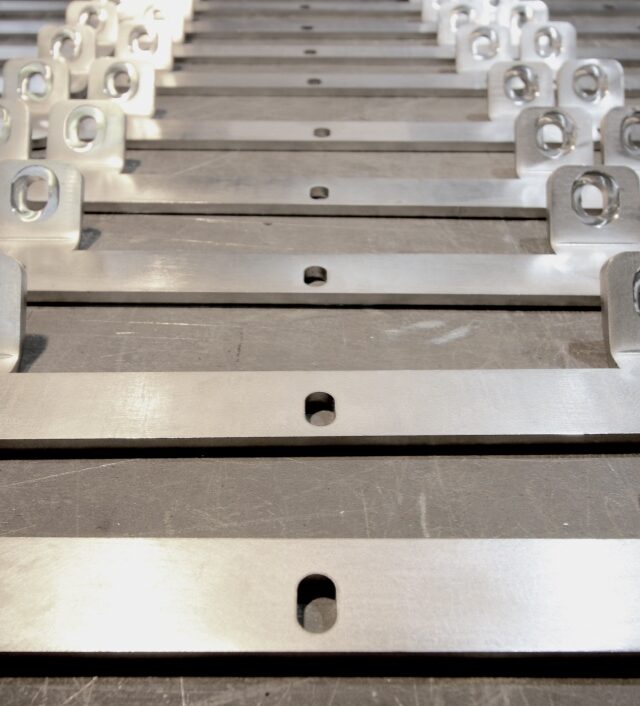

Steel milling executed with rigid setups and high-torque tools for best results.

We offer steel milling services for structural elements and machine parts.

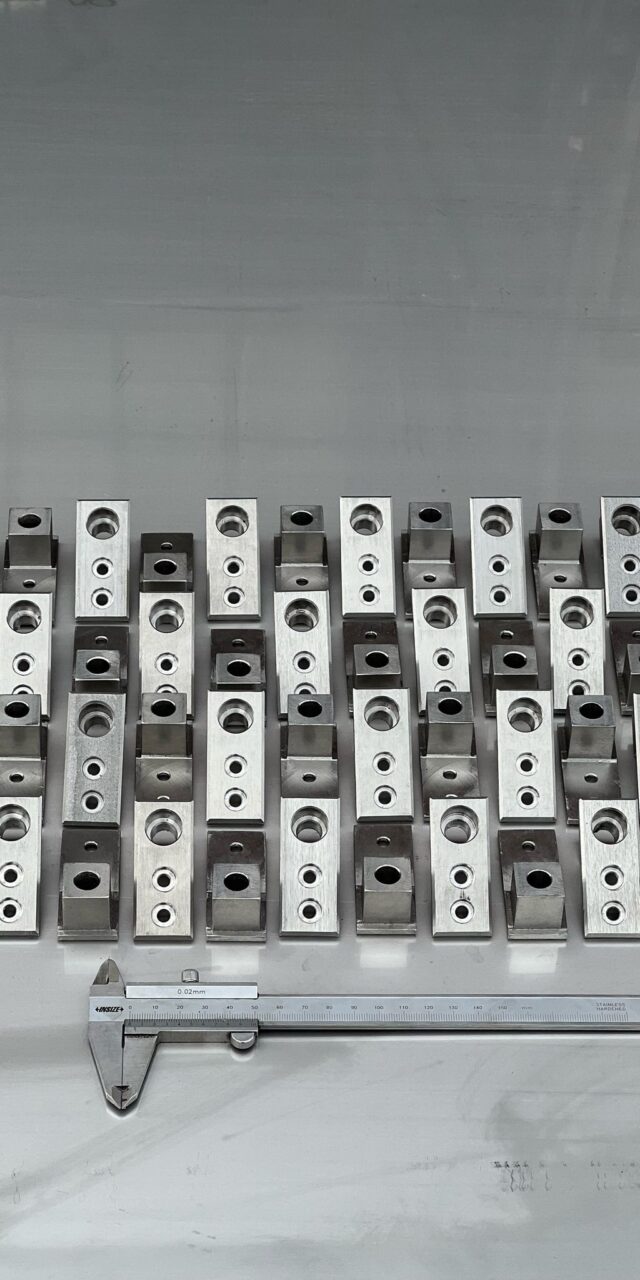

Modern CNC milling centers and quality control.

Each stage of production is subject to strict quality control - from material verification to measurement of the finished part. We also offer additional services such as threading, grinding and technical painting.

Flexible implementation of steel projects

We carry out unit, series and prototype orders. We deliver finished parts protected, ready for further assembly or immediate use. We work quickly, reliably and with full commitment.

Steel milling ensures durable, high-precision components in harsh-use applications.

Realizations

ContactContact us

Steel millingFAQ

We mill structural steel (S235, S355), tool steel, wear-resistant steel (Hardox), acid-resistant steel and alloy steel.

Yes – we carry out single pieces, as well as larger batches and serial production.

We maintain tolerances of ±0.01 mm as standard. For precision parts, we can use more accurate parameters.

Yes, we help convert the technical drawing or sketch into a CAD/CAM model suitable for CNC milling.

Yes – we offer grinding, painting, as well as corrosion protection or surface treatment according to customer needs.