Stainless steel milling for demanding industries

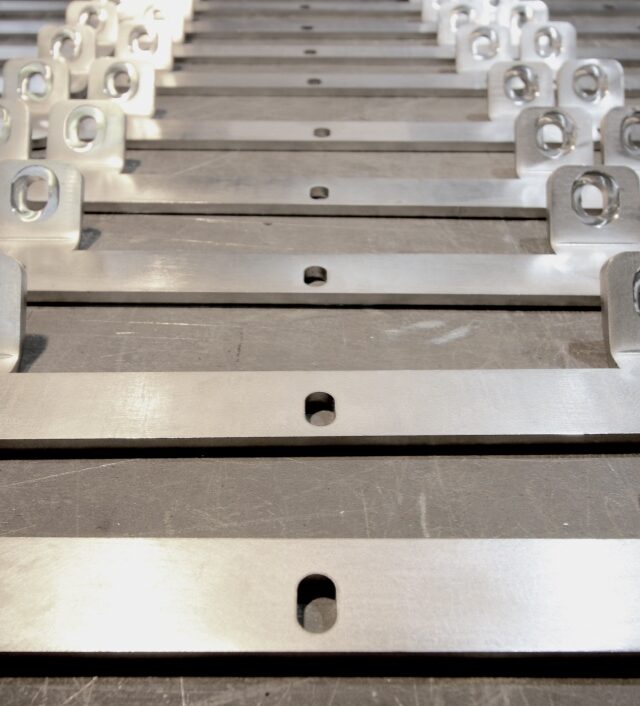

Stainless steel is a unique material - corrosion resistant, aesthetically pleasing and durable, but at the same time requiring the right approach in the machining process. At Metallbauform, we offer precision CNC milling of stainless steel, taking into account its thermal, mechanical and structural properties. Our realizations go to the food, pharmaceutical, chemical and architectural industries, among others.

We machine stainless steel of AISI 304, 316 and other grades, depending on the customer's needs. We guarantee accuracy, clean machining and aesthetic finish of parts.

We machine stainless steel of AISI 304, 316 and other grades, depending on the customer's needs. We guarantee accuracy, clean machining and aesthetic finish of parts.

Stainless steel milling that meets cleanroom, food-safe, and medical specifications.

We handle stainless steel milling with precision tools and surface control.

CNC technology tailored to the properties of stainless steel

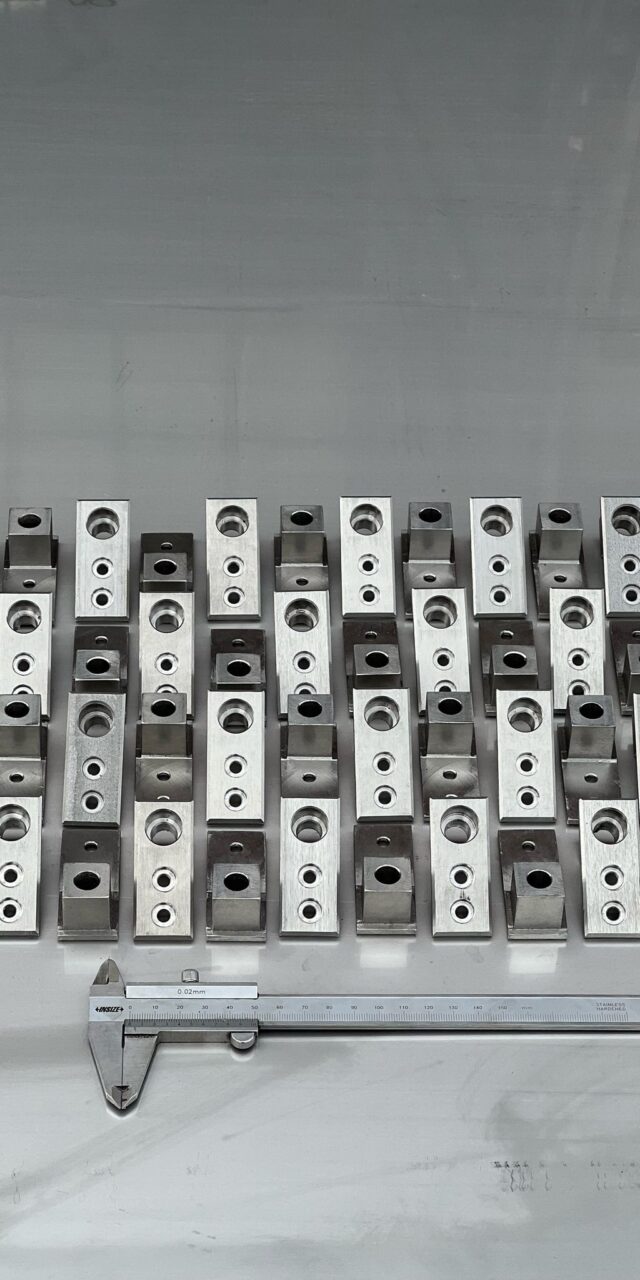

The stainless steel milling process requires special tools and cooling to maintain surface quality and prevent overheating of the material. Our CNC machining centers are equipped with appropriate systems for working with difficult-to-machine materials, which allows us to maintain stable parameters even in larger production runs.

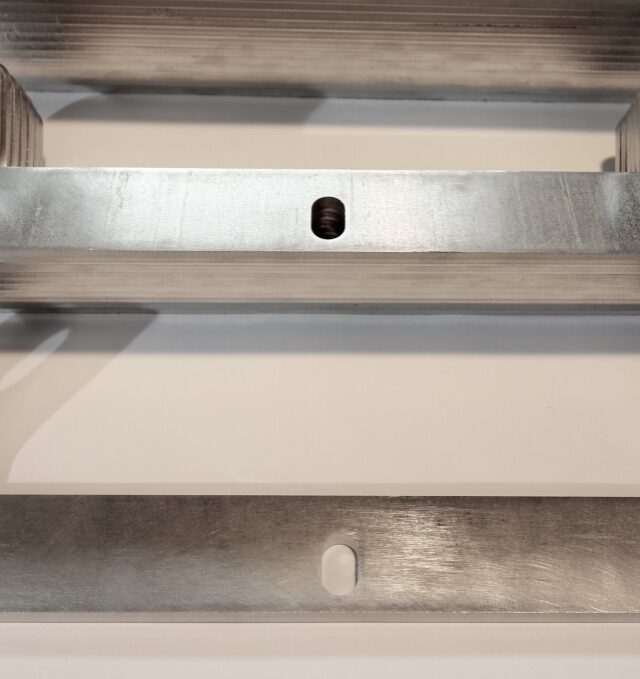

Each detail is subjected to accurate measurements - both dimensional and visual. We also offer post-processing - grinding, brushing, polishing - to achieve a result in line with customer expectations.

Each detail is subjected to accurate measurements - both dimensional and visual. We also offer post-processing - grinding, brushing, polishing - to achieve a result in line with customer expectations.

A trusted partner in stainless steel projects

We perform stainless steel milling both according to customer documentation and based on a jointly developed project. We help optimize the project in terms of processing, which allows us to shorten the execution time and reduce material costs.

We carry out orders for customers from all over Poland and the EU. We supply finished parts to industrial plants, construction companies, machinery manufacturers and individual customers. Our experience allows us to meet even the most demanding projects.

We carry out orders for customers from all over Poland and the EU. We supply finished parts to industrial plants, construction companies, machinery manufacturers and individual customers. Our experience allows us to meet even the most demanding projects.

Stainless steel milling suitable for visible, corrosion-resistant surfaces.

Realizations

ContactContact us

Milling of stainless steel

FAQ

1. What grades of stainless steel do you mill?

Mostly AISI 304 and 316, but we also work with other types – according to project requirements.

2. Do you mill components for industries with higher sanitary requirements?

Yes. We make components according to standards for the food and pharmaceutical industries.

3. Can I have the surface finished after milling?

Of course – we offer brushing, polishing, satin finishing and other forms of aesthetic finishing.

4. Do you also realize assembly?

For larger structures or components – yes, we provide transportation and assembly at the site of the project.

5. Can you help in choosing the right grade of stainless steel?

Yes, our technologists advise on the best material depending on the operating conditions and the purpose of the component.