Plastic milling - the ideal solution for industry and design

Plastics are versatile materials - lightweight, durable, corrosion-resistant and easy to machine. At Metallbauform, we offer precision CNC milling of plastics such as polyamide, POM, PVC, PTFE, PC or PMMA. We dedicate our services to customers in various industries - from industry to advertising and industrial design.

We manufacture technical parts, housings, structural details, prototypes and components for machinery and equipment. We ensure high quality cutting, smooth surfaces and repeatability for larger series.

We manufacture technical parts, housings, structural details, prototypes and components for machinery and equipment. We ensure high quality cutting, smooth surfaces and repeatability for larger series.

Plastics milling is ideal for lightweight, non-conductive, and precision parts.

We perform plastics milling for housings, fixtures, and technical components.

CNC machine tools and experience in plastics machining

Plastics require a different approach than metals - appropriate cutting speeds, tools and cooling conditions. Our CNC machines are designed to work with plastics, avoiding deformation and ensuring perfect part finishes.

We perform both flat milling and three-dimensional milling. Thanks to the experience of our operators, we are able to advise on optimal design solutions and reduce the risk of technological errors. We also combine machining with other processes - such as drilling, threading and engraving.

We perform both flat milling and three-dimensional milling. Thanks to the experience of our operators, we are able to advise on optimal design solutions and reduce the risk of technological errors. We also combine machining with other processes - such as drilling, threading and engraving.

Flexible approach to your project

We serve individual clients, designers, industrial plants and advertising agencies. All you need to do is provide a drawing or CAD file, and we will prepare a quote and suggest the most effective manufacturing technology. We carry out plastic milling in batches or individually, also as prototypes.

We deliver orders on time, with attention to every detail - ready for further assembly or use without additional processing.

We deliver orders on time, with attention to every detail - ready for further assembly or use without additional processing.

Our plastics milling supports medical, electronics, and consumer product industries.

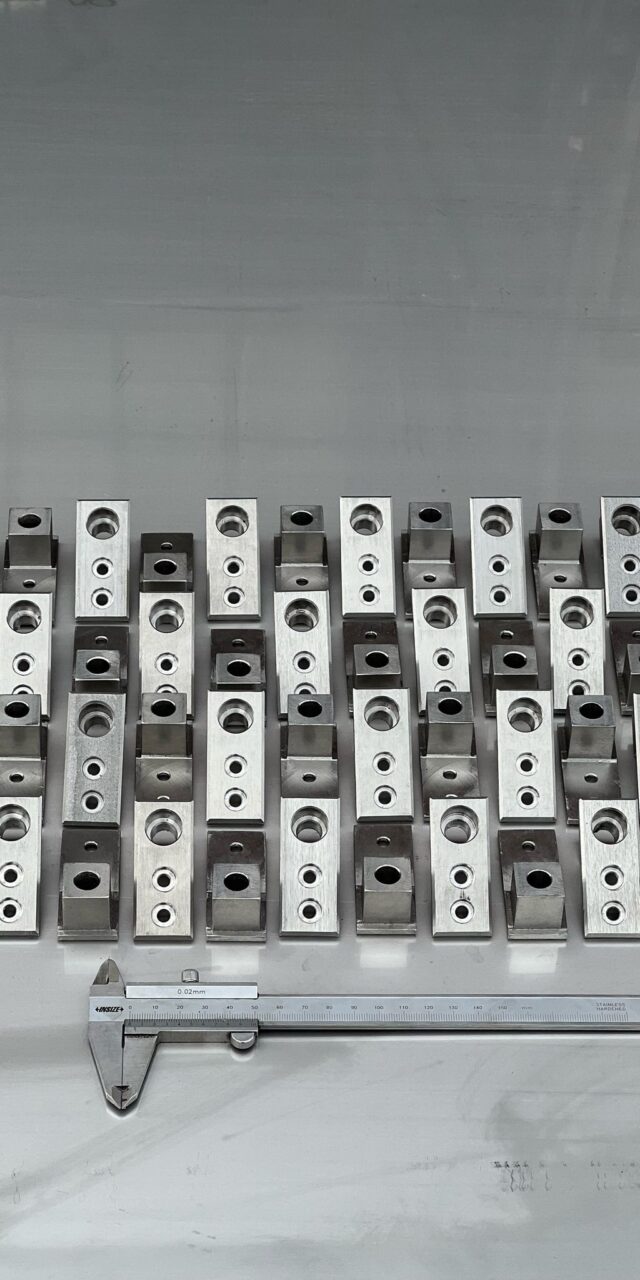

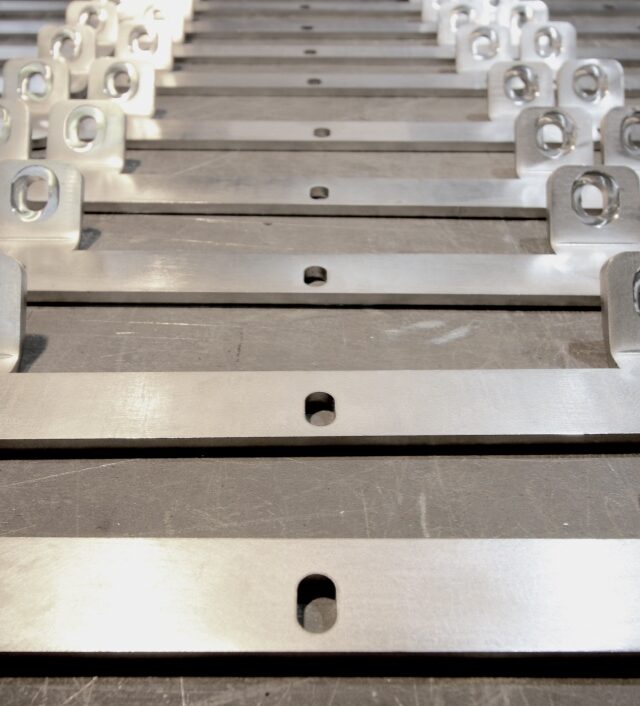

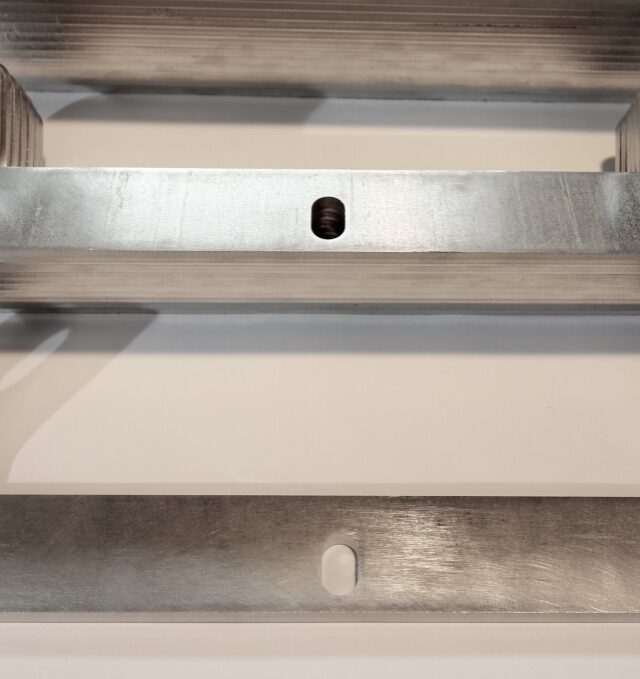

Realizations

ContactContact us

Milling of plasticsFAQ

1. What kind of plastics do you mill?

Mostly POM, PA, PVC, PC, PTFE, PMMA (plexiglass) – we select the material according to the needs of the project.

2. Is it possible to make a plastic prototype with you?

Yes, we realize single pieces and prototype series – ideal for builders, designers and startups.

3. Do plastics require additional processing after milling?

No – we offer a very smooth finish, ready to use without further processing.

4. What file formats do you accept?

STEP, DXF, DWG, PDF – if needed, we can also prepare a CAM file based on the drawing.

5. Do you mill transparent materials, such as Plexiglas?

Yes – we mill PMMA and other transparent materials, taking care of smooth edges and aesthetics