Precision CNC turning of metals and plastics

CNC turning is a machining method that produces precise axisymmetrical parts such as shafts, bushings, flanges or rings. At Metallbauform, we offer state-of-the-art CNC turning services for customers in a variety of sectors - industrial, automotive, medical and many others.

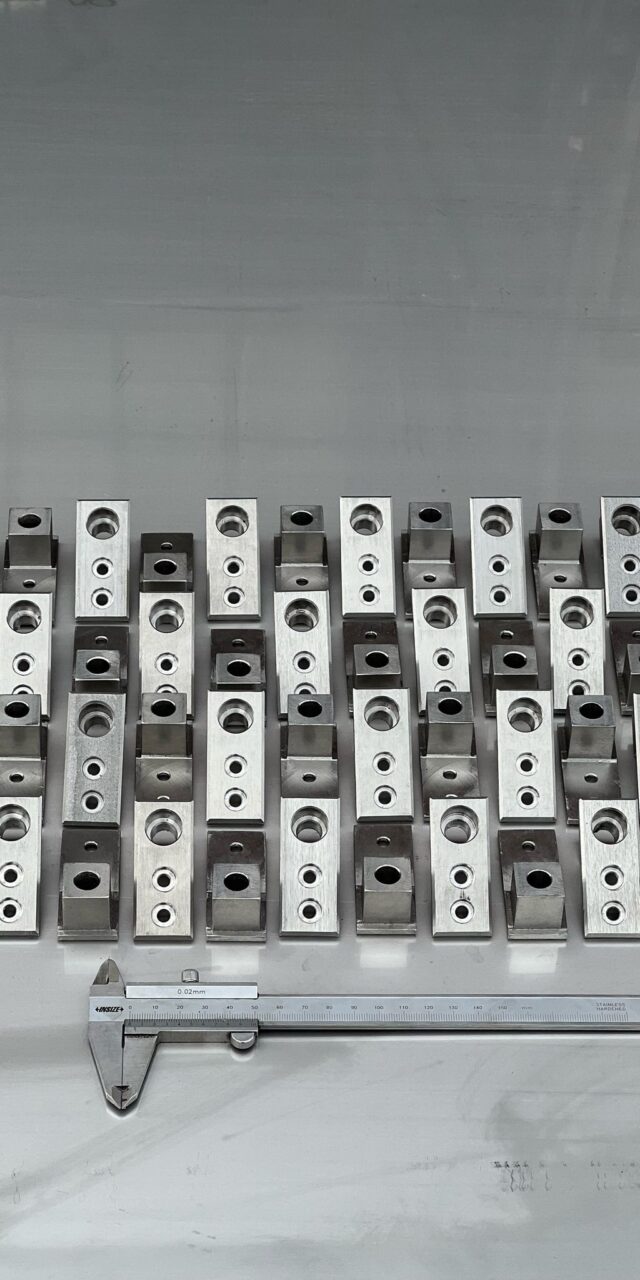

We turn black steel, stainless steel, aluminum, brass, bronze and engineering plastics. Thanks to numerical control, we achieve high repeatability and accuracy - even in large production runs.

We turn black steel, stainless steel, aluminum, brass, bronze and engineering plastics. Thanks to numerical control, we achieve high repeatability and accuracy - even in large production runs.

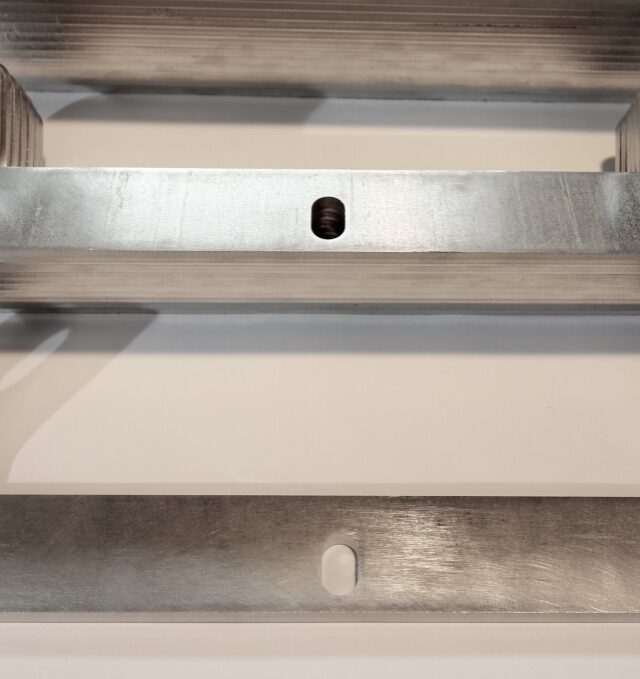

CNC turning enables the production of round, concentric parts with high accuracy.

We offer CNC turning for shafts, sleeves, and cylindrical parts in various materials.

Turning machine park and extensive capabilities

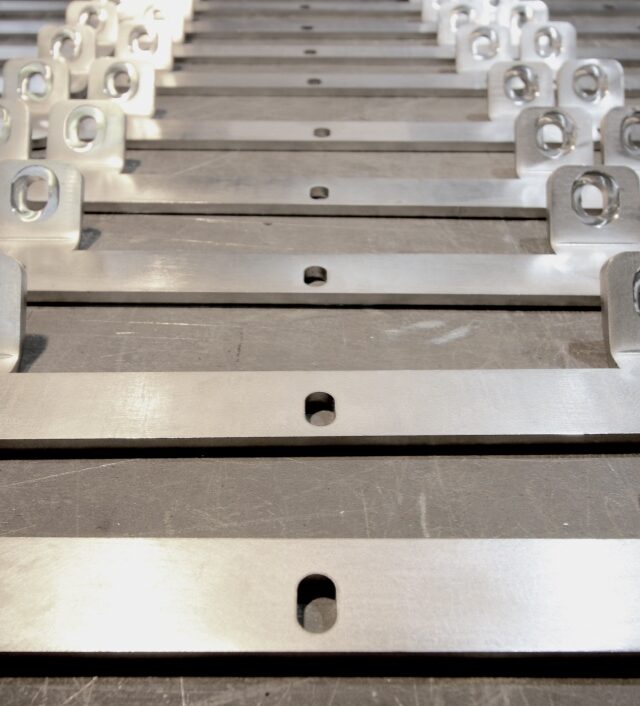

Our CNC turning machines are equipped with tools for external turning, internal turning, threading, drilling and grooving. This allows us to produce a part ready for assembly in a single cycle - without the need to transfer between stations.

We accept orders for parts of various diameters and lengths. Each part undergoes dimensional verification, and if necessary, we also offer finishing - grinding, polishing, anodizing or painting.

We accept orders for parts of various diameters and lengths. Each part undergoes dimensional verification, and if necessary, we also offer finishing - grinding, polishing, anodizing or painting.

Fast turnaround and technical support

Metallbauform's team provides support at every stage - from the analysis of the project, through the selection of materials, to the implementation and delivery of finished parts. We realize serial, unit and prototype orders.

We work flexibly, adjusting the process to the customer's requirements and the characteristics of the order. We deliver finished parts in protected packaging - ready for immediate use.

We work flexibly, adjusting the process to the customer's requirements and the characteristics of the order. We deliver finished parts in protected packaging - ready for immediate use.

CNC turning ensures consistent surface finish and precise diameters.

Realizations

ContactContact us

CNC turningFAQ

1. What materials can be turned at your company?

Steel, stainless steel, aluminum, brass, bronze and selected engineering plastics (POM, PA).

2. Do you perform threading and drilling on the lathe?

Yes, our CNC lathes allow you to perform threading, drilling and grooving operations.

3. Is it possible to fulfill an order for a single detail?

Of course – we also realize unit orders and prototypes.

4. What are the maximum dimensions of turning?

We can turn parts up to 500 mm in diameter and up to 500 mm in length – depending on the project.

5. Do you offer finishing?

Yes – if necessary, we perform additional finishing operations or painting of finished parts