What is CNC milling and when is it worth using it?

At Metallbauform we offer professional CNC milling of steel, aluminum, stainless steel and non-ferrous metal parts. We serve both industrial customers and manufacturers of utility, mechanical, architectural or advertising components.

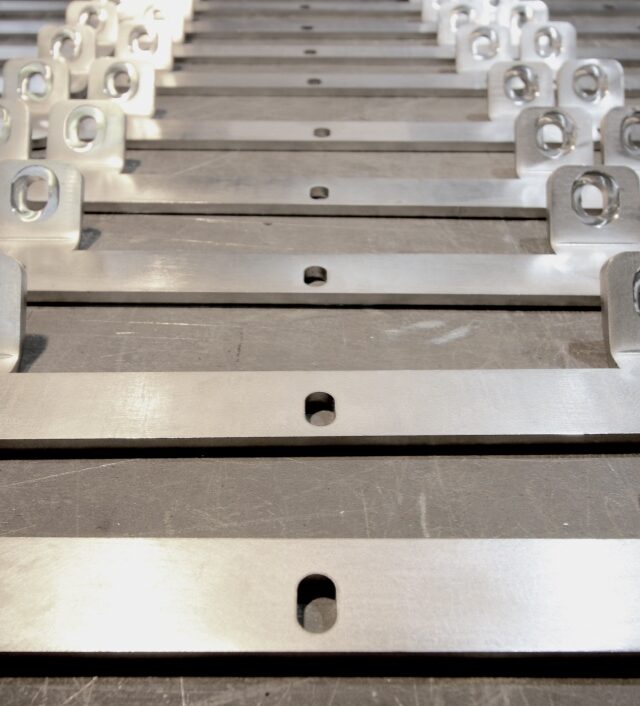

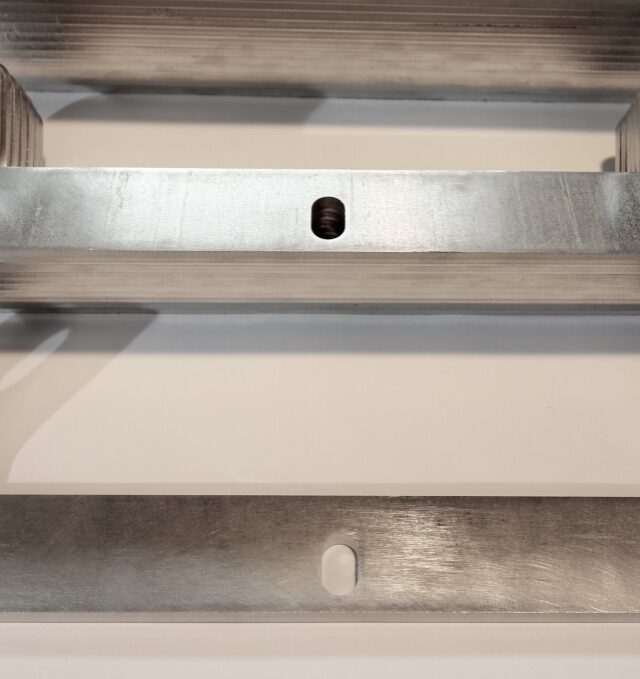

CNC milling enables the creation of complex geometries with tight tolerances.

We perform CNC milling for a range of industries including automotive and aerospace.

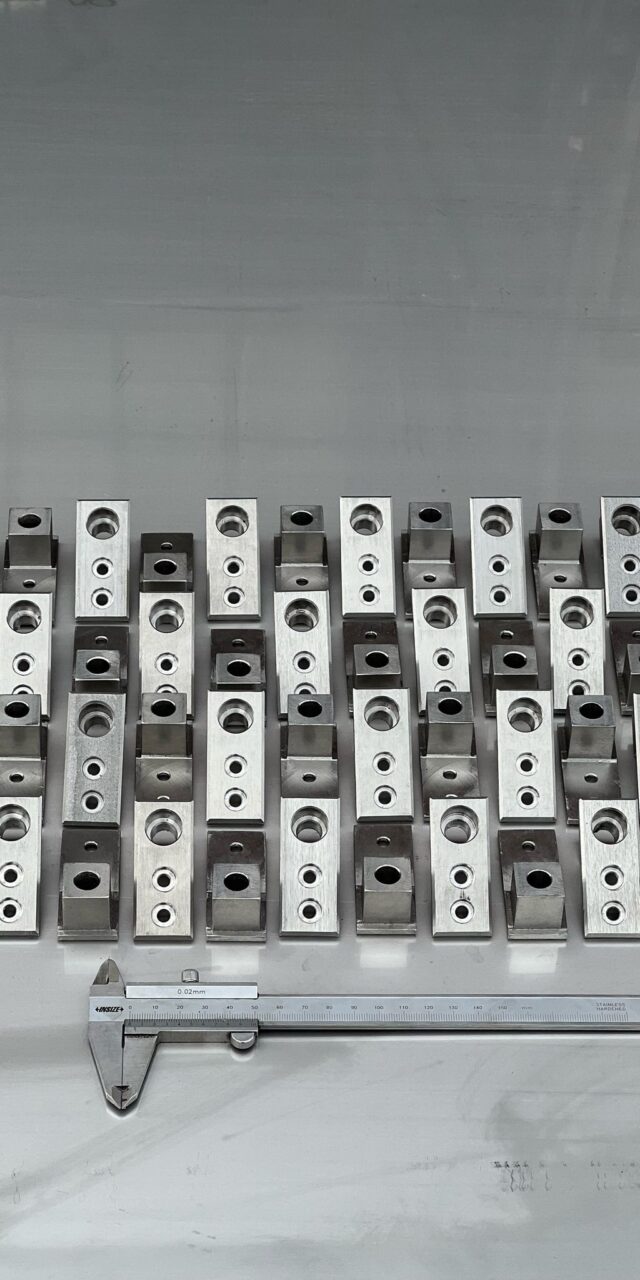

Accuracy and repeatability - our strengths in milling.

We enable milling of elements of various dimensions - from small technical details to larger structural components. We focus on quality, timeliness and process control - each batch undergoes dimensional and visual verification before shipment to the customer.

Comprehensive service - from file to finished part

We also offer additional services such as threading, drilling and anodizing. We deliver the finished parts to the site, packaging them safely and suitable for further assembly or distribution.

CNC milling provides precision shaping for small and large components.

Realizations

ContactContact us

CNC millingFAQ

We make structural, technical, decorative elements, machine parts, panels, handles and other details that require high precision.

Steel, stainless steel, aluminum, brass, bronze, as well as plastics – it all depends on the project.

Yes. If the customer does not have a ready-made CAM file, our technologists will help convert the drawing into a production file and optimize the tool path.

Depending on the project, we achieve tolerances ranging from ±0.01 mm to ±0.05 mm. For technical parts, we perform detailed quality control.

The price depends on the size of the batch, complexity and type of material. We price each order individually after reviewing the documentation.