Professional aluminum milling - lightness and precision.

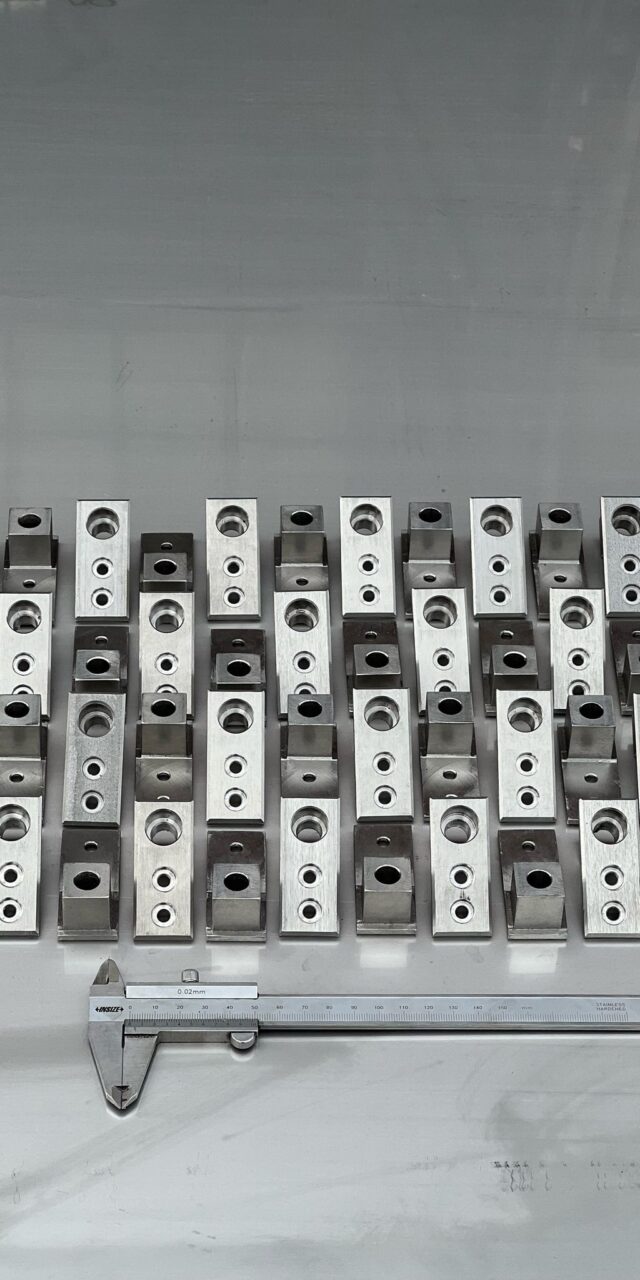

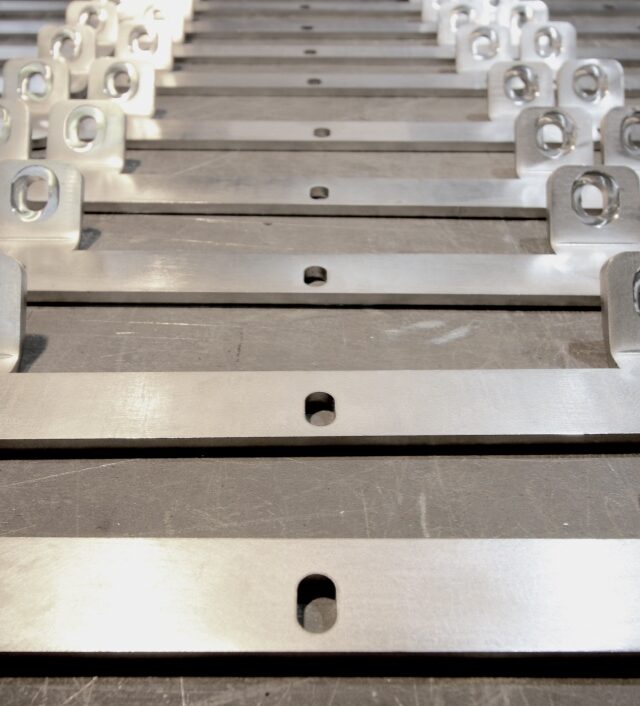

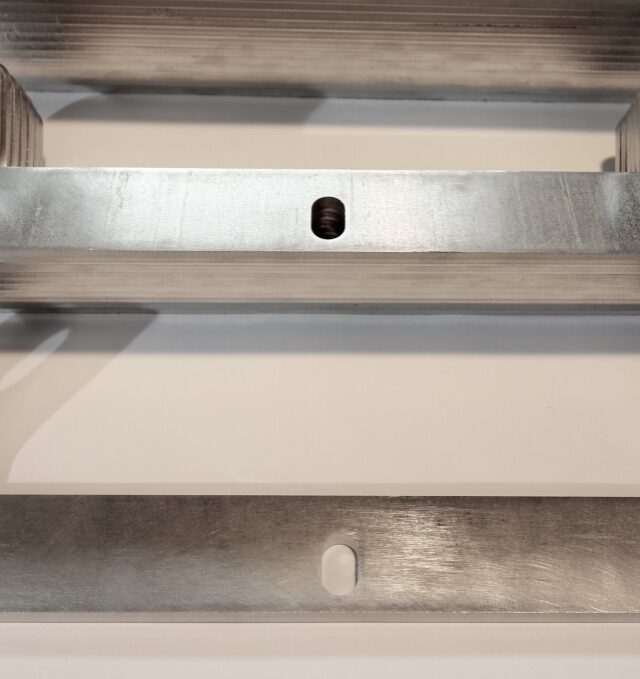

Aluminum milling is one of the most widely used methods in industry, especially where lightness of material and aesthetics of workmanship are important. Aluminum, due to its physical properties, allows for fast and efficient milling with high precision. At Metallbauform, we offer CNC aluminum milling services with tolerances to hundredths of a millimeter - ideal for technical, architectural and advertising industries.

We direct our services to manufacturing companies, design offices and individual customers. We mill small precision components as well as larger structural components. Regardless of the complexity of the project, we always focus on accuracy, repeatability and timeliness.

We direct our services to manufacturing companies, design offices and individual customers. We mill small precision components as well as larger structural components. Regardless of the complexity of the project, we always focus on accuracy, repeatability and timeliness.

Aluminum milling for components that require strength without added weight.

We offer aluminum milling with excellent thermal control and chip removal.

Machine park and modern aluminum processing methods

In the aluminum milling process, the right choice of parameters - speed, cooling and tool type - is crucial. We have modern CNC machining centers that allow us to realize even the most complex parts with the highest surface quality. As a result, our milled parts do not require additional finishing.

In addition, we offer the possibility of anodizing aluminum after milling, which allows to protect the surface and give it an attractive appearance. We handle unit, prototype and serial orders - each order is priced individually, taking into account its specifics.

In addition, we offer the possibility of anodizing aluminum after milling, which allows to protect the surface and give it an attractive appearance. We handle unit, prototype and serial orders - each order is priced individually, taking into account its specifics.

Flexibility of cooperation and individual approach

We realize that every project has different needs - that's why we offer full technical support from the moment we receive the file to the final execution. Our technologists help optimize the project for milling, select appropriate machining strategies and suggest alternative solutions where possible.

We deliver the finished parts within the agreed deadline, packaged in a way that protects them from damage. We serve companies from all over Poland and abroad, and our experience also allows us to carry out projects requiring special certificates or documentation.

We deliver the finished parts within the agreed deadline, packaged in a way that protects them from damage. We serve companies from all over Poland and abroad, and our experience also allows us to carry out projects requiring special certificates or documentation.

Our aluminum milling is ideal for parts used in transportation and electronics.

Realizations

ContactContact us

Aluminum milling

FAQ

1. Is aluminum suitable for precision milling?

Yes, thanks to its softness and structure, it allows for very precise shapes and smooth surfaces.

2. What file formats are needed for the project?

We prefer STEP, DXF, DWG or PDF files with dimensions. We can also help you prepare a 3D model based on a sketch.

3. Can you do anodizing after milling?

Yes, we work with trusted subcontractors and offer anodizing in various colors and hardnesses.

4. Can you complete prototype orders?

Of course. We also realize single pieces and prototypes – especially for startups, builders and designers.

5. How long does it take to complete an order?

Turnaround time depends on the complexity and size of the series – usually from 3 to 10 working days.