Professional steel machining on modern CNC lathes

Steel is one of the most widely used materials in industry - extremely durable, resistant to mechanical stress and at the same time capable of very precise processing. At Metallbauform, we offer modern steel turning services using CNC machines that ensure repeatability, perfect shape reproduction and excellent surface quality. We handle orders from a wide range of industries: heavy industry, mechanical engineering, steel construction, hydraulics, as well as spare parts manufacturers.

Among others, we turn structural steel (S235, S355), tempered steels, tool steels and alloy steels. We manufacture both standard parts and parts with complex geometries. We treat each project individually, matching machining parameters to the properties of the material and customer requirements.

Among others, we turn structural steel (S235, S355), tempered steels, tool steels and alloy steels. We manufacture both standard parts and parts with complex geometries. We treat each project individually, matching machining parameters to the properties of the material and customer requirements.

Steel turning for tough applications requiring structural integrity and longevity.

We offer steel turning for robust, high-precision mechanical components.

Modern machinery and experience in steel processing

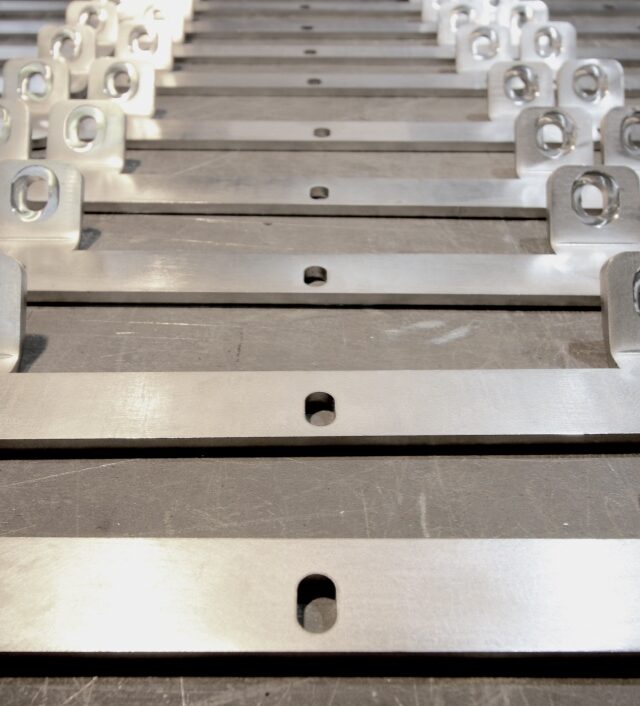

Our CNC turning centers are equipped with high-end chucks, cutting tools and cooling systems, allowing stable and accurate machining of steel - even at high material hardness. We can perform external turning, internal turning, threading, grooving and drilling operations without handling the workpiece. As a result, the entire process is optimized in terms of cost and time.

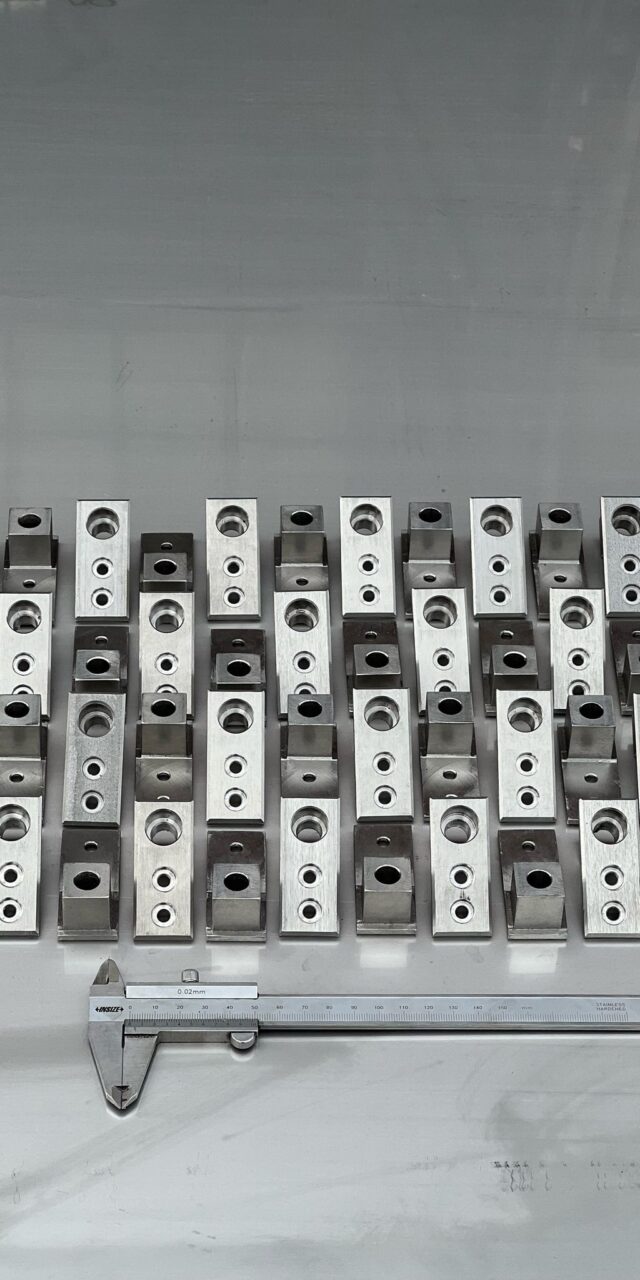

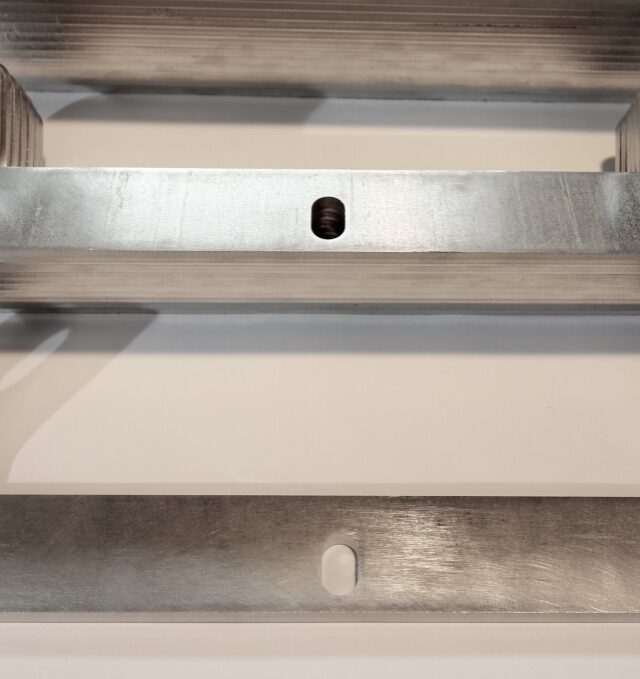

High-precision manufacturing allows us to obtain parts that meet industrial standards - ready for further assembly or operation in demanding conditions. Each detail undergoes dimensional and visual inspection, and we include measurement documentation upon request.

High-precision manufacturing allows us to obtain parts that meet industrial standards - ready for further assembly or operation in demanding conditions. Each detail undergoes dimensional and visual inspection, and we include measurement documentation upon request.

Flexible approach and comprehensive implementation

We offer realization of unit, prototype and serial orders. We serve customers from all over Poland and the EU, ensuring professional communication, timeliness and the possibility of a quick quote. Our team provides technological advice - we help optimize the project in terms of processing, choose the right steel grade and plan production in the most efficient way.

We carry out orders comprehensively - from the analysis of the drawing to the delivery of finished, safely packaged parts. Thanks to our experience, you can be sure that each part will be made with the utmost care.

We carry out orders comprehensively - from the analysis of the drawing to the delivery of finished, safely packaged parts. Thanks to our experience, you can be sure that each part will be made with the utmost care.

Steel turning creates strong parts suited to load-bearing and high-stress systems.

Realizations

ContactContact us

Turning of steelFAQ

1. What types of steel do you turn most often?

We most often work with S235/S355 structural steel, alloy steel, tool steel and tempering steels.

2. Do you also perform finishing after turning?

Yes, we offer grinding, technical painting, corrosion protection and assembly of finished components

3. Can I order the manufacture of a single part?

Of course – we carry out single-part, prototype and series orders. We are flexible.

4. How long does it take to complete a steel turning order?

Usually from 3 to 10 working days – depending on the complexity and size of the batch. We set deadlines individually.

5. Do you make technological documentation?

Yes, if the customer does not have a ready file, we help prepare drawings or convert to CAM format.