Where does TIG welding perform well?

TIG (Tungsten Inert Gas) welding is one of the cleanest and most precise welding techniques. Thanks to its ability to control the arc and the secondary material, TIG is used wherever the aesthetics of the weld and the highest quality of workmanship matter - such as in the food, pharmaceutical and chemical industries, in stainless steel and aluminum structures.

At Metallbaform, we offer TIG welding of stainless steel, aluminum, titanium and non-ferrous metals. We work in accordance with quality standards, also offering welding of thin-walled details and pipelines with higher requirements.

At Metallbaform, we offer TIG welding of stainless steel, aluminum, titanium and non-ferrous metals. We work in accordance with quality standards, also offering welding of thin-walled details and pipelines with higher requirements.

TIG welding delivers clean, precise welds on stainless steel and thin materials.

We specialize in TIG welding for decorative and structural metalwork.

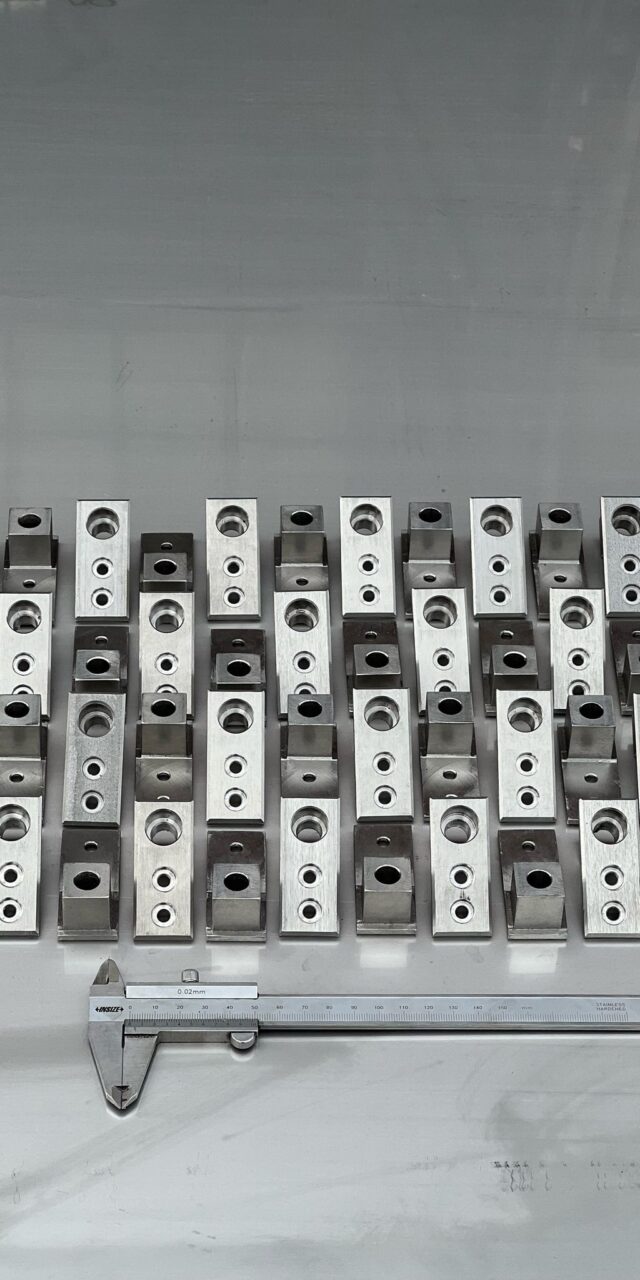

Equipment and quality control at the highest level

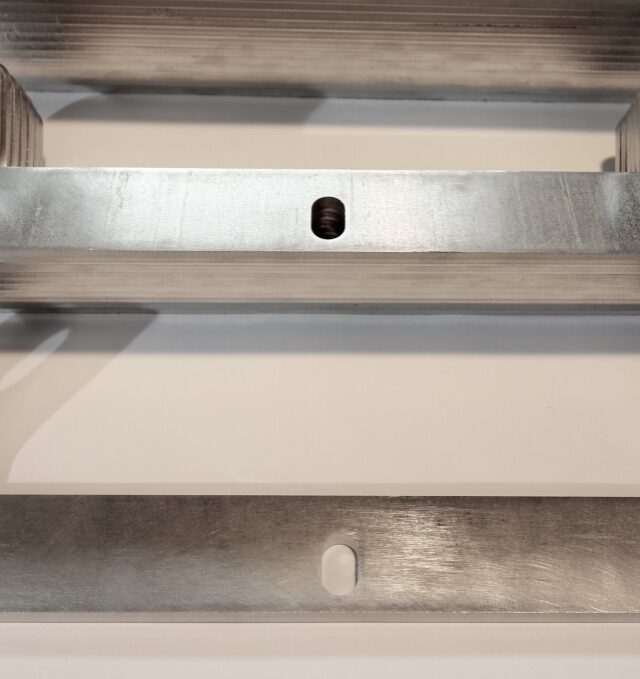

Our TIG workstations are equipped with state-of-the-art power sources, water cooling, and sets for welding pipes and small-section workpieces. Welders have up-to-date certificates and experience in working with high-alloy materials. The quality of the welds is checked depending on the requirements - visually, penetration or by leak tests.

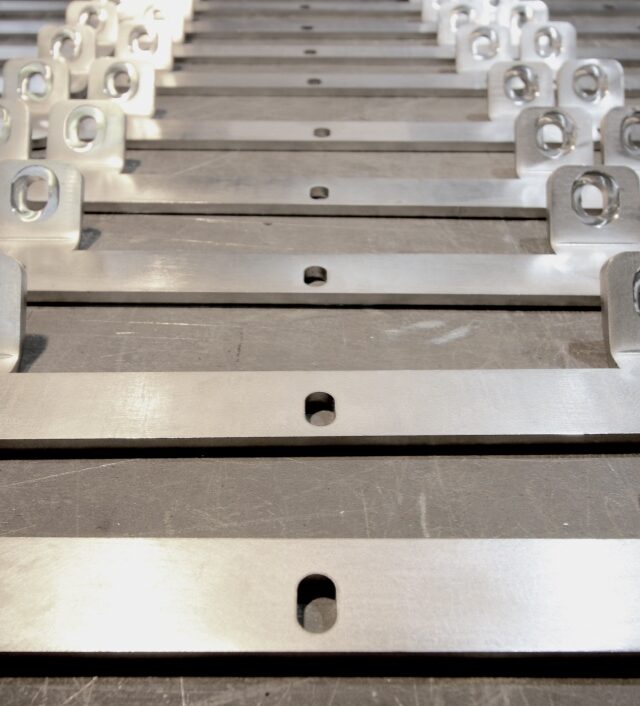

TIG welds are characterized by very low spatter, smooth surface and perfect finish. We also offer welding without filler material and peripheral (automatic) welds.

TIG welds are characterized by very low spatter, smooth surface and perfect finish. We also offer welding without filler material and peripheral (automatic) welds.

Applications and manufacturing flexibility

TIG welding is ideal for the production of stainless steel railings, pressure vessels, structural frames, equipment for the food and medical industries. We offer the ability to join different materials, precision fabrication of parts with complex geometries and aesthetics that do not require further processing.

Thanks to our flexible approach and comprehensive project handling, we are able to carry out both serial and unit orders - always to the highest standards.

Thanks to our flexible approach and comprehensive project handling, we are able to carry out both serial and unit orders - always to the highest standards.

TIG welding offers spatter-free joints and minimal post-processing.

Realizations

ContactContact us

TIG welding

FAQ

1. What materials can be TIG welded?

Stainless steel, aluminum, titanium, copper and other metals that require precise and aesthetic welding.

2. Do you weld thin-walled tubes or components?

Yes – TIG allows you to weld thin-walled workpieces with great control and without the risk of overheating.

3. Do TIG welds require grinding?

Not always – TIG welds are very aesthetically pleasing and often do not require further processing.

4. Do you perform test welds and NDT tests?

Yes – we perform VT, PT, RT tests and full quality documentation upon request.

5. Is it possible to perform TIG welding on site?

Yes – we offer mobile TIG stations for installation and assembly projects.